Cart

2025 Top Uses of Steel Wire Mesh: Applications, Benefits, and Trends

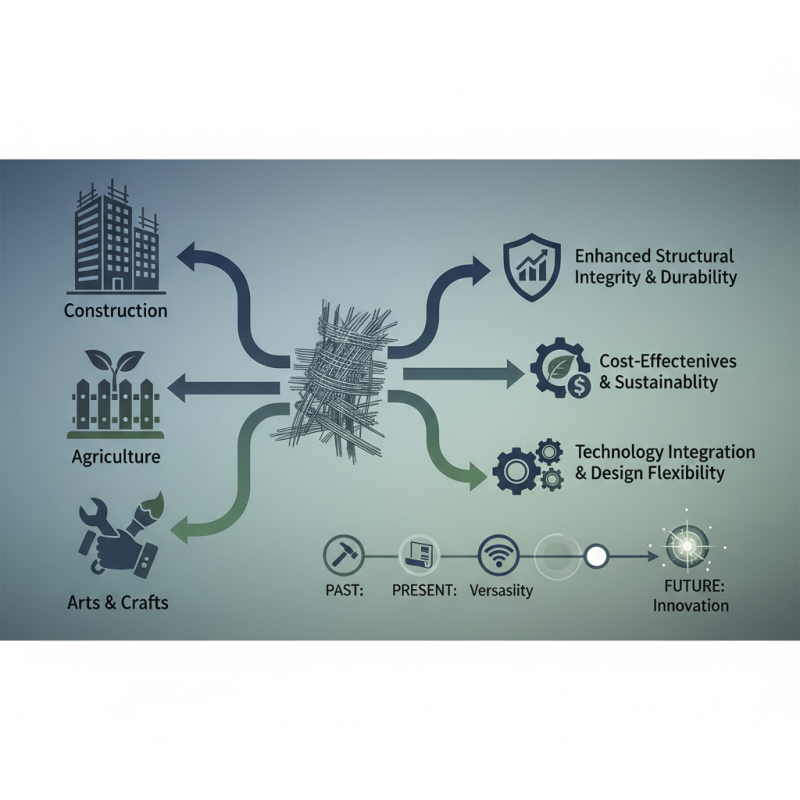

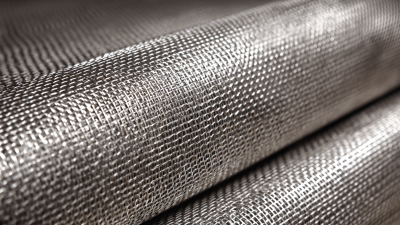

In recent years, the versatility and utility of steel wire mesh have grown exponentially, establishing it as a vital component across various industries. According to Dr. Emily Chen, a renowned expert in construction materials, "Steel wire mesh is not just a reinforcement tool; it’s a bridge to innovation in construction and beyond." As we look toward 2025, the potential applications of steel wire mesh continue to expand, particularly in sectors such as construction, agriculture, and even arts and crafts.

The advantages of steel wire mesh are numerous, ranging from enhanced structural integrity to cost-effectiveness and sustainability. With increasing emphasis on eco-friendly practices and durable building solutions, steel wire mesh is becoming the go-to choice for architects and engineers aiming to meet modern construction demands. This evolution is further supported by ongoing trends that emphasize technology integration and design flexibility, making steel wire mesh an indispensable material in future projects. As we explore the top uses of steel wire mesh, we highlight its applications, benefits, and the trends poised to reshape its role in various industries.

Top Applications of Steel Wire Mesh in Construction and Architecture

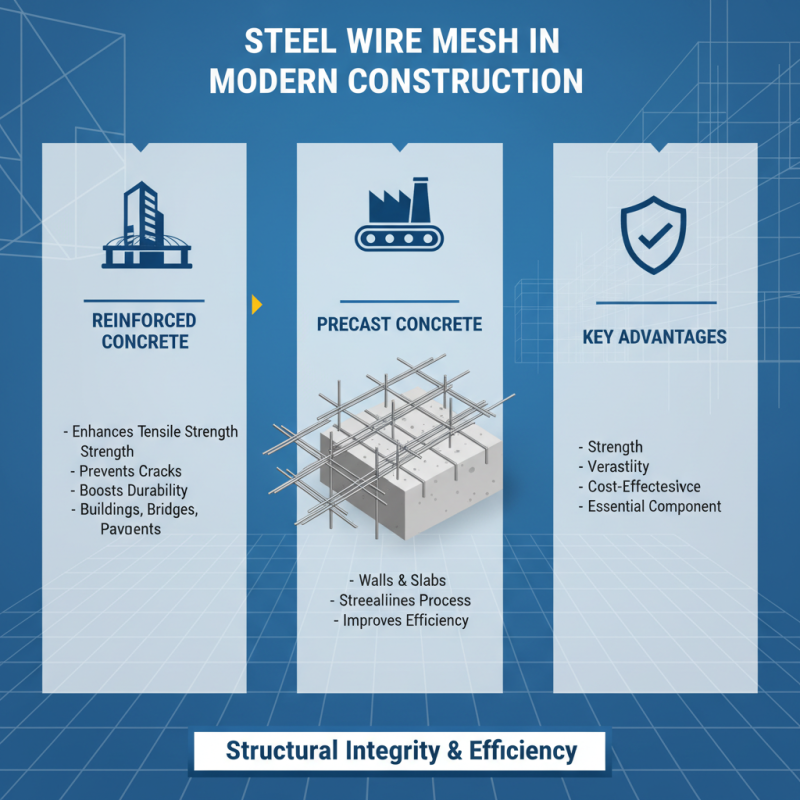

Steel wire mesh has become an essential component in modern construction and architecture due to its strength, versatility, and cost-effectiveness. One of its primary applications is in reinforced concrete structures. The mesh provides superior tensile strength, preventing cracks in concrete and enhancing overall durability. This application is particularly crucial in constructing buildings, bridges, and pavements, where structural integrity is paramount. Additionally, steel wire mesh is increasingly used in precast concrete products, including walls and slabs, streamlining the construction process and improving efficiency.

Another significant use of steel wire mesh is in architectural design, where it serves both functional and aesthetic purposes. Architects often incorporate wire mesh into facades and screen walls, allowing for creative designs while ensuring safety and structural support. The open framing of wire mesh facilitates airflow and natural light, contributing to energy-efficient building practices. Moreover, it can be finished in various coatings and finishes to enhance its visual appeal, making it a favorite choice for contemporary designs. As sustainability becomes a focus in architecture, steel wire mesh's recyclability and longevity emphasize its role in eco-friendly construction practices, further solidifying its position in the industry.

Benefits of Using Steel Wire Mesh in Various Industries

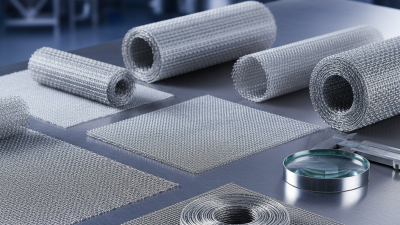

Steel wire mesh has become increasingly indispensable across various industries, thanks to its unique combination of durability, flexibility, and cost-effectiveness. According to a report by Research and Markets, the global steel wire mesh market is projected to grow at a CAGR of 7.2% from 2023 to 2028, driven by its applications in construction, agriculture, and industrial sectors. One of the primary benefits of steel wire mesh is its ability to enhance structural integrity. In construction, it is commonly used for reinforcing concrete, providing crucial tensile strength that helps prevent cracking and deformation.

Moreover, the agricultural industry has also recognized the advantages of using steel wire mesh for fencing and crop protection. A study from the International Journal of Engineering & Technology highlighted that using steel wire mesh in farming operations can lead to a reduction in livestock loss by up to 30%. This type of mesh offers robust protection against predators while allowing optimal air circulation, which is vital for crop health. Additionally, its longevity and resistance to environmental factors make it a more sustainable option compared to traditional fencing materials, aligning with the growing trend towards eco-friendly agricultural practices.

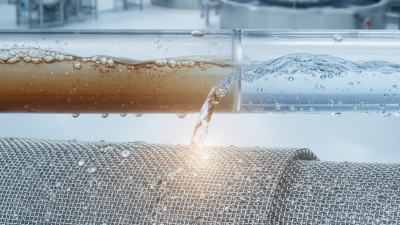

In the industrial sector, steel wire mesh serves various purposes, from filtration systems to safety barriers. The rise in automation and industrial safety regulations has further fueled the demand for reliable safety solutions. A recent report by Statista indicated that investments in workplace safety technologies are expected to increase by 20% over the next five years. Steel wire mesh benefits these systems by providing a strong yet lightweight solution that preserves visibility and access while enhancing overall safety.

Emerging Trends in Steel Wire Mesh Technology for 2025

Emerging trends in steel wire mesh technology are expected to reshape various industries by 2025, focusing on sustainability and enhanced performance.

One significant development is the integration of smart technology into steel wire mesh products. Industry reports indicate that the global smart material market is projected to grow at a CAGR of 14.8% from 2021 to 2026. This trend involves incorporating sensors into wire mesh, enabling real-time monitoring of structural integrity, which is invaluable in construction and infrastructure management. By utilizing advanced monitoring systems, businesses can enhance safety measures and reduce maintenance costs significantly.

Moreover, the shift towards eco-friendly materials is gaining momentum, with a growing emphasis on the recyclability of steel wire mesh. The World Steel Association reports that over 85% of steel is recycled worldwide, highlighting the industry's commitment to sustainability. Innovations in production techniques, such as the use of electric arc furnaces, are expected to further reduce the carbon footprint of steel manufacturing, aligning with the global drive towards greener technologies. As organizations seek to minimize environmental impact, the demand for sustainable wire mesh solutions will rise, leading to broader adoption across various sectors, including construction, agriculture, and mining.

Environmental Impact and Sustainability of Steel Wire Mesh

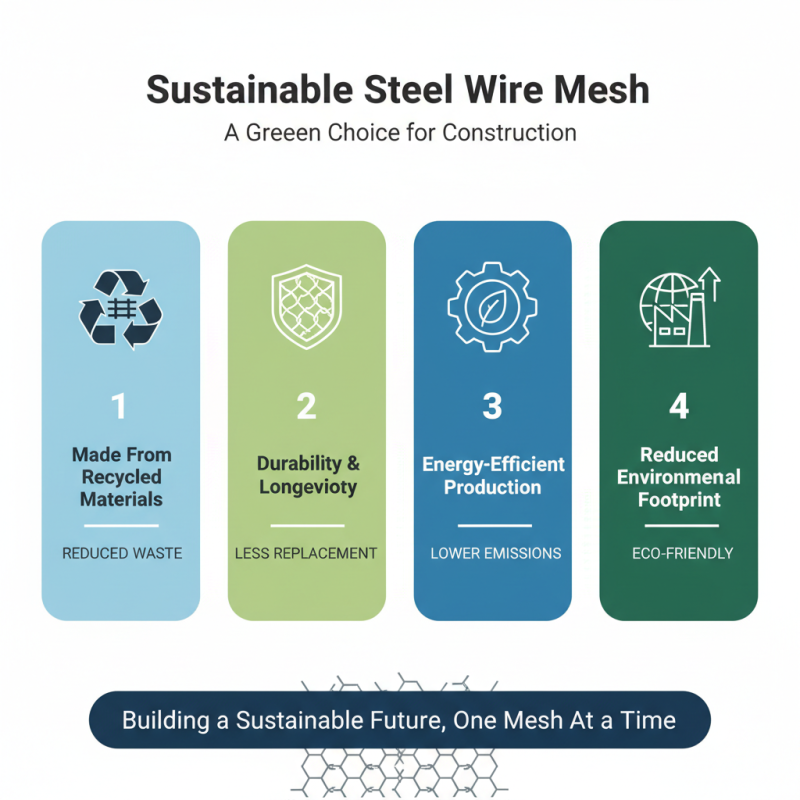

The environmental impact and sustainability of steel wire mesh are critical considerations in modern construction and industrial practices. Steel wire mesh, made primarily from recycled materials, has a lesser environmental footprint compared to other building materials. Its durability and longevity reduce the need for frequent replacements, which in turn lowers resource consumption over time. Moreover, the production process of steel wire mesh has evolved to incorporate energy-efficient practices and technologies, further minimizing carbon emissions.

Sustainability in using steel wire mesh also extends to its recyclability at the end of its life cycle. Unlike many alternatives, steel can be efficiently recycled without losing its structural integrity. This characteristic not only conserves natural resources but also significantly reduces landfill waste. As industries increasingly focus on environmental stewardship, integrating steel wire mesh into projects aligns with green building practices. The material's versatility allows it to be utilized in diverse applications, from construction reinforcement to architectural designs, showcasing its potential to support sustainable development goals effectively.

Future Innovations in Steel Wire Mesh Applications and Design

As we move toward 2025, innovations in steel wire mesh applications and design are projected to significantly enhance various industries. Research from the Global Steel Wire Mesh Market Report indicates a compound annual growth rate (CAGR) of approximately 5.4% from 2021 to 2026, driven by an increasing demand for sustainable construction materials. The integration of advanced manufacturing technologies, such as 3D printing and automated welding techniques, is facilitating the production of more complex wire mesh structures that not only improve tensile strength but also reduce material waste.

Emerging applications of steel wire mesh in civil engineering, particularly in seismic reinforcement, are gaining traction. According to a study by the American Concrete Institute, using steel wire mesh for concrete reinforcement can enhance durability and load-bearing capacities by up to 30% in seismic-prone areas. Additionally, advancements in protective coatings are expanding the lifespan of steel wire mesh, making it a more viable option in harsh environments. This trend toward enhanced durability aligns with global sustainability goals, as longer-lasting materials contribute to reduced resource consumption over time. The future of steel wire mesh is thus poised for revolutionary changes that will reshape its role across multiple sectors, from construction to environmental engineering.

2025 Top Uses of Steel Wire Mesh: Applications, Benefits, and Trends

| Application Area | Description | Benefits | Current Trends |

|---|---|---|---|

| Construction | Used for reinforcement in concrete structures. | Increases strength and durability. | Innovative designs for better aesthetics. |

| Agriculture | Used for fencing and crop protection. | Effective wildlife control and crop safeguarding. | Sustainable materials and eco-friendly practices. |

| Industrial | Used in manufacturing processes and equipment. | Enhances operational efficiency and machinery life. | Automation and smart manufacturing applications. |

| Architecture | Incorporated into decorative elements and facades. | Aesthetic appeal and modern design flexibility. | Integration with green technologies and designs. |

| Transportation | Used in the construction of road and rail infrastructure. | Improves safety and structural integrity. | Emphasis on longevity and maintenance reduction. |

Related Posts

-

What is Wire Mesh Panels and How Are They Used in Various Industries

-

2025 Guide: How to Choose the Right Wire Mesh Screen for Your Project

-

Top 10 Tips for Choosing the Right Stainless Steel Mesh for Your Needs

-

Why Stainless Steel Mesh is the Best Choice for Your Filtration Needs

-

Top 5 Benefits of Using Metal Mesh for Your Home and Office Needs

-

How to Choose the Right Stainless Steel Wire Mesh for Your Project