Cart

Why Choose Steel Mesh for Your Construction Projects? Benefits and Applications Explained

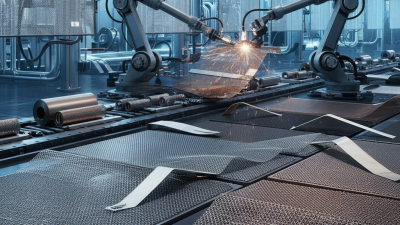

When it comes to modern construction projects, the choice of materials plays a crucial role in determining the overall quality, durability, and sustainability of the structure. Among the various options available, steel mesh stands out as a preferred solution due to its numerous benefits and versatile applications. Designed to enhance the strength and stability of concrete and other building elements, steel mesh has become integral to construction practices worldwide.

One of the primary advantages of steel mesh is its exceptional tensile strength and resistance to cracking, which significantly extends the life of structures while reducing maintenance costs. Additionally, its lightweight nature and ease of installation allow for efficient construction processes, making it an ideal choice for both large-scale commercial projects and smaller residential builds. This introduction of steel mesh not only optimizes construction timelines but also contributes to safer building practices.

Furthermore, the adaptability of steel mesh ensures its effective application across a variety of construction scenarios, from paving driveways to reinforcing walls and slabs. As sustainability continues to gain prominence in the industry, steel mesh's recyclability and low environmental impact further solidify its position as a top choice. In this article, we will delve deeper into the many benefits and applications of steel mesh, highlighting why it should be an essential component in your next construction endeavor.

Benefits of Using Steel Mesh in Construction Projects

Steel mesh has become an essential material in construction projects due to its numerous benefits and versatile applications. One of the primary advantages of using steel mesh is its remarkable strength and durability. According to the American Concrete Institute (ACI), structures reinforced with steel mesh can significantly increase load-bearing capacities and withstand environmental stressors, leading to enhanced longevity. This durability makes steel mesh an ideal choice for high-load applications such as bridges, parking garages, and industrial flooring, where safety and structural integrity are paramount.

Additionally, steel mesh contributes to cost-effectiveness in construction. A report from the National Institute of Standards and Technology (NIST) indicates that using steel mesh in concrete composites can reduce the overall material costs by optimizing the use of concrete, which is often the most expensive component of construction projects. Moreover, its lightweight properties simplify transportation and handling on-site, decreasing labor costs and improving overall project timelines. The efficiency of installation also allows for faster project completion, providing contractors with a competitive edge in today’s fast-paced construction industry.

The adaptability of steel mesh further enhances its appeal in construction. It can be utilized in various applications, including slab-on-grade floors, precast concrete elements, and masonry walls, making it suitable for residential, commercial, and industrial projects alike. As the construction industry continues to evolve, the integration of innovative materials like steel mesh is essential for meeting the growing demands for sustainable and resilient building practices.

Variety of Applications for Steel Mesh in Different Industries

Steel mesh has emerged as a critical component in various construction projects due to its versatility and durability. According to industry reports, such as those from the World Steel Association, the global steel mesh market is projected to grow at a rate of 5% annually, driven by increasing demands in sectors like construction, manufacturing, and infrastructure. One of the key applications of steel mesh is in concrete reinforcement. It significantly enhances the tensile strength of concrete structures, making them more resilient against cracking and deformation under heavy loads.

Beyond traditional construction, steel mesh finds applications in the automotive and aerospace industries. Its lightweight yet robust properties make it ideal for use in parts where reducing weight while maintaining strength is essential. For instance, studies indicate that utilizing steel mesh in components can reduce the overall vehicle weight by 20%, improving fuel efficiency and reducing emissions. Additionally, in the agricultural sector, steel mesh is utilized for fencing and pest control, offering sustainable solutions for farmers while ensuring durability against environmental factors. This wide range of applications showcases steel mesh's adaptability across diverse industries, reinforcing its importance in modern construction and manufacturing processes.

Comparative Strength: Steel Mesh vs. Traditional Reinforcement Materials

When comparing the strength of steel mesh to traditional reinforcement materials, it is crucial to acknowledge the fundamental differences that impact structural integrity and longevity. Steel mesh provides enhanced tensile strength and ductility, allowing it to better absorb and distribute loads across a construction site. This flexibility greatly reduces the risk of cracking and deformation, common issues seen in projects that rely solely on conventional reinforcement bars. The uniform distribution of forces in the steel mesh results in improved performance under stress, making it a robust choice for diverse construction applications.

Additionally, steel mesh often offers superior resistance to corrosion and environmental degradation compared to traditional materials. This resilience is particularly advantageous in demanding conditions, such as coastal or industrial environments where corrosion could compromise structural safety. The incorporation of steel mesh can lead to longer-lasting structures, reducing maintenance costs over time. Overall, the comparative strength of steel mesh positions it as an optimal solution for modern construction projects that demand durability and reliability.

Comparative Strength: Steel Mesh vs. Traditional Reinforcement Materials

This bar chart illustrates the tensile strength comparison between steel mesh and traditional reinforcement materials. As shown, steel mesh offers significantly higher tensile strength, making it a superior choice for various construction applications.

Cost-Effectiveness of Steel Mesh in Long-Term Construction Projects

When considering long-term construction projects, the cost-effectiveness of steel mesh becomes evident. Steel mesh reinforces concrete structures, providing enhanced strength and durability without significantly increasing the overall budget. Unlike traditional reinforcing methods, steel mesh can streamline labor costs and reduce material waste, making it a smart choice for large-scale projects. Additionally, its longevity means fewer repairs and replacements in the future, which translates into substantial savings over time.

Tips for using steel mesh effectively include ensuring proper installation to maximize its load-bearing capacities. Collaborate with skilled professionals who understand the nuances of working with steel mesh, as improper techniques can undermine its benefits. Consider the environmental benefits as well; steel mesh is often made from recycled materials, contributing to sustainable construction practices.

Investing in quality steel mesh not only enhances structural integrity but also minimizes costs by reducing the likelihood of costly repairs down the line. The initial expenditure can be offset by the long-term savings associated with maintenance and durability. Make informed choices about your steel mesh options to ensure your project remains economically viable throughout its lifespan.

Sustainability and Environmental Impact of Steel Mesh Usage

The use of steel mesh in construction projects presents several compelling sustainability benefits. One of the primary advantages is its high recyclability. Steel is one of the most recycled materials globally, which means that when a structure is dismantled or no longer needed, the steel mesh can be repurposed for new projects. This reduces the demand for new raw materials and minimizes waste, significantly lowering the environmental footprint of construction activities.

Moreover, steel mesh contributes to energy efficiency during the construction phase and throughout the lifespan of a building. Its strength allows for the creation of lighter and more innovative structural designs, which can lead to reduced energy consumption in both material production and transportation. Additionally, structures reinforced with steel mesh can provide better durability and longevity, which minimizes the need for frequent repairs or replacements, further diminishing their overall environmental impact. By opting for steel mesh, construction projects can align with sustainable practices and promote a healthier planet.

Benefits and Applications of Steel Mesh in Construction

| Benefit/Application | Description | Sustainability Impact |

|---|---|---|

| High Strength | Steel mesh provides excellent tensile strength, enhancing the durability of structures. | Less material is needed, leading to reduced environmental impact. |

| Versatile Application | Can be used in various applications, including concrete reinforcement, underlays, and fencing. | Adaptable to different needs, minimizing waste. |

| Cost-Effective | Reduces labor and material costs due to its efficiency. | Lower infrastructure costs for better economic sustainability. |

| Corrosion Resistance | Special coatings available to enhance the lifespan of steel mesh. | Promotes longevity, reducing the need for replacements and waste. |

| Recyclability | Steel mesh can be fully recycled at the end of its life cycle. | Supports circular economy principles, reducing landfill waste. |

Related Posts

-

2025 Top Trends in Metal Mesh Sheet Innovation for Industrial Applications

-

Top 5 Benefits of Using Metal Mesh for Your Home and Office Needs

-

Top 10 Tips for Choosing the Right Steel Wire Mesh for Your Projects

-

Understanding Expanded Metal: The Versatile Material Transforming Modern Architecture and Design

-

How to Choose the Right Stainless Steel Wire Mesh for Your Project

-

Exploring the Versatility of Perforated Steel Sheets in Modern Architecture and Design