Cart

Top Benefits of Using Sheet Steel in Construction and Manufacturing Projects

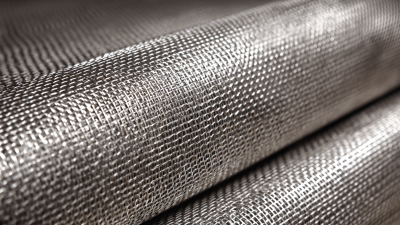

Sheet steel has emerged as a fundamental material in the fields of construction and manufacturing, offering a plethora of advantages that make it an ideal choice for a wide range of applications. As a versatile and durable product, sheet steel provides strength and resilience, enabling builders and manufacturers to create structures and products that withstand the test of time. Its inherent properties, such as excellent formability and weldability, allow for intricate designs and robust constructions, ensuring that both aesthetic and structural requirements are met.

Furthermore, the benefits of using sheet steel extend beyond mere functionality. The material is lightweight yet strong, allowing for easier handling and transportation, which can significantly reduce labor costs and time on site. The availability of various coatings and finishes also enhances its adaptability, enabling it to meet specific environmental challenges while maintaining its integrity and appearance. As sustainability becomes increasingly important in modern construction practices, sheet steel's recyclability further positions it as an environmentally friendly choice, aligning with contemporary goals of reducing waste and promoting sustainable resource use.

In summary, the adoption of sheet steel in construction and manufacturing projects provides a combination of strength, versatility, and sustainability that is difficult to match with other materials. The continuing evolution of engineering techniques and design innovation will further highlight the crucial role of sheet steel as the industry advances toward a more durable and eco-conscious future.

Advantages of Sheet Steel in Structural Applications

Sheet steel has become a cornerstone in structural applications within the construction and manufacturing industries, thanks to its impressive strength-to-weight ratio, versatility, and cost-effectiveness. According to a report by the World Steel Association, steel accounts for about 65% of the total weight of construction materials used globally. This dominance underscores the remarkable properties of sheet steel that make it ideal for a range of structural applications. Its ability to provide high tensile strength while remaining lightweight allows architects and engineers to design innovative structures without compromising safety or performance.

Moreover, sheet steel is renowned for its durability and resistance to environmental factors such as corrosion and extreme weather conditions. The American Institute of Steel Construction (AISC) indicates that structures made from steel can last over 50 years with minimal maintenance, significantly reducing lifecycle costs. The ease of fabrication and availability of various finishes also enhance its appeal in construction projects, making it adaptable for everything from commercial buildings to intricate industrial frameworks. The combination of these benefits allows projects to be completed more efficiently while ensuring long-term structural integrity, which is critical in today's fast-paced construction environment.

Cost-Effectiveness of Sheet Steel in Construction Projects

The cost-effectiveness of sheet steel in construction projects is one of the primary reasons for its widespread use in the industry. With rising material costs, it becomes crucial for construction managers and manufacturers to choose materials that offer both durability and affordability. Sheet steel is known for its remarkable strength-to-weight ratio, allowing builders to use less material without compromising structural integrity. This translates into significant savings on both material costs and transportation, as lighter materials are easier to handle and ship.

Moreover, sheet steel's versatility and ease of fabrication contribute to its cost-effectiveness. It can be manipulated into various shapes and sizes, making it suitable for a range of applications, from framing to roofing. This adaptability not only minimizes waste during the manufacturing process but also reduces labor costs, as fewer specialized workers are needed to work with the material. Additionally, the long lifespan of sheet steel means that projects require less frequent repairs or replacements, further enhancing its value over time. By integrating sheet steel into their designs, construction projects can achieve a balance between initial investment and long-term savings.

Durability and Longevity of Sheet Steel Materials

The durability and longevity of sheet steel materials make them an invaluable choice in construction and manufacturing projects. Sheet steel is known for its exceptional strength-to-weight ratio, which allows it to withstand immense loads and stresses. This inherent strength ensures that structures can endure harsh environmental conditions, including high winds, heavy snowfall, and seismic activities. As a result, buildings and infrastructures benefit from enhanced safety and reduced maintenance costs over time, as sheet steel resists cracking, warping, and other forms of deterioration that can affect other materials.

Moreover, the longevity of sheet steel is further bolstered by its resistance to corrosion when properly treated or coated. This attribute is particularly beneficial in environments exposed to moisture or harsh chemicals, where other materials might fail. The protective coatings can significantly extend the lifespan of sheet steel, enabling it to maintain its structural integrity and appearance for decades. Consequently, using sheet steel not only results in immediate cost savings due to lower maintenance, but also contributes to a more sustainable approach in construction, as fewer replacements and repairs are needed throughout the life cycle of a project.

Versatility of Sheet Steel in Various Manufacturing Processes

Sheet steel is a fundamental material in a myriad of manufacturing processes, offering exceptional versatility that caters to diverse industries. According to the World Steel Association, sheet steel accounted for approximately 32% of global steel production in 2020, underscoring its significance in sectors such as automotive, construction, and appliances. Its ease of fabrication allows for processes like stamping, bending, and welding, making it suitable for complex shapes that meet rigorous design specifications. The lightweight nature of sheet steel also contributes to improved fuel efficiency in vehicles, providing a sustainable solution that aligns with modern manufacturing needs.

Furthermore, the adaptability of sheet steel extends beyond traditional applications. The Metal Construction Association reports that pre-painted sheet steel is gaining momentum in building envelope systems due to its aesthetic appeal and durability. It can be easily customized in terms of thickness, finish, and coating, which allows for tailored solutions that meet specific project requirements. This flexibility ensures that manufacturers can innovate and respond swiftly to market trends, positioning sheet steel as a key player in contemporary production processes. The future of manufacturing will increasingly rely on such materials, making sheet steel an invaluable asset across various sectors.

Top Benefits of Using Sheet Steel in Construction and Manufacturing Projects

The chart below illustrates the primary benefits of using sheet steel in various construction and manufacturing processes. The data represents the perceived importance of each benefit based on industry feedback.

Sustainability Aspects of Using Sheet Steel in Industry

The use of sheet steel in construction and manufacturing projects offers significant sustainability benefits. According to the World Steel Association, steel is one of the most recycled materials globally, with over 85% of steel products being recycled at the end of their lifecycle. This high recycling rate not only reduces the amount of waste sent to landfills but also conserves natural resources and energy consumption. By utilizing recycled steel, the carbon footprint of new steel production is diminished considerably; in fact, producing steel from scrap can reduce greenhouse gas emissions by up to 75% compared to using virgin materials.

Moreover, sheet steel is known for its durability and strength, contributing to the longevity of buildings and products made from it. A report by the Global Steel Innovations Forum highlights that structures built with steel can have a lifespan extending over 50 years, requiring less frequent repairs or replacements. This durability minimizes the need for additional raw material extraction and production, further reducing energy use and emissions associated with manufacturing new building materials. As industries increasingly focus on sustainable practices, the adoption of sheet steel represents a proactive approach to enhancing sustainability while maintaining structural integrity and performance.

Related Posts

-

2025 Top 10 Decorative Metal Sheets for Stylish Home Decor and Unique Designs

-

2025 How to Choose the Best Steel Stair Treads for Safety and Durability

-

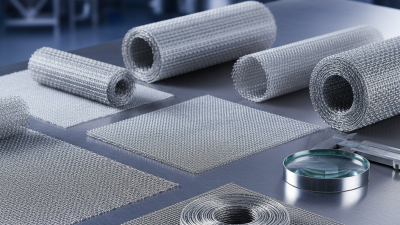

2025 Guide: How to Choose the Right Wire Mesh Screen for Your Project

-

Understanding Expanded Metal: The Versatile Material Transforming Modern Architecture and Design

-

Top 10 Aluminum Stair Treads for Safety and Durability

-

Top 10 Tips for Choosing the Right Stainless Steel Mesh for Your Needs