Cart

10 Best FRP Grating Solutions for Durable and Cost-Effective Industrial Applications

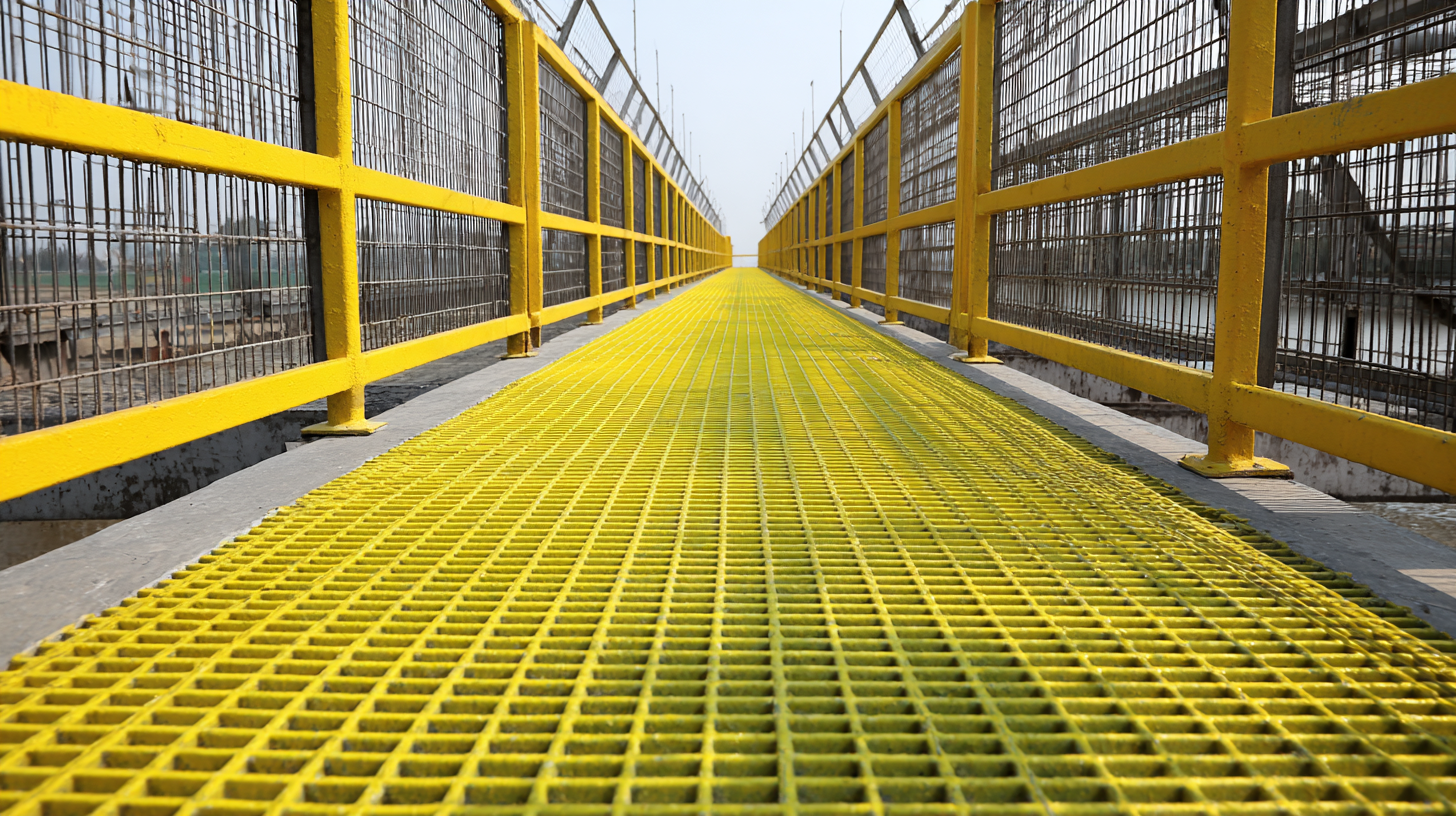

In the realm of industrial applications, the choice of flooring solutions plays a crucial role in ensuring safety, efficiency, and longevity. Among the various available options, FRP grating has emerged as a versatile solution that meets the demanding requirements of a wide range of environments. According to a report by MarketsandMarkets, the global market for fiberglass reinforced plastic (FRP) composites is projected to reach $8.3 billion by 2026, reflecting a growing recognition of the benefits of materials such as FRP grating in various industries.

FRP grating offers unique advantages, including excellent chemical resistance, lightweight construction, and significant durability, making it ideal for use in sectors such as chemicals, wastewater treatment, and food processing. The National Institute of Standards and Technology noted that adopting advanced materials like FRP can lead to increased operational efficiency, contributing to cost savings over time due to lower maintenance and replacement needs. As industries increasingly prioritize sustainability and cost-effectiveness, understanding the spectrum of FRP grating solutions becomes imperative for decision-makers looking to invest in robust flooring technologies.

In this article, we will explore the 10 best FRP grating solutions that stand out in the industrial landscape, focusing on their durability, cost-effectiveness, and application versatility. By identifying the right type of FRP grating, companies can enhance their operational resilience while ensuring compliance with safety and environmental regulations.

Top Features of FRP Grating for Industrial Use in 2025

FRP (Fiberglass Reinforced Plastic) grating is becoming an increasingly popular choice for various industrial applications due to its unique features that enhance durability and cost-effectiveness. In 2025, the demand for FRP grating is projected to soar, with market reports indicating a Compound Annual Growth Rate (CAGR) of around 6.5% through the next five years. This growth is primarily driven by the material's lightweight nature, which allows for easier installation and maintenance compared to traditional materials such as steel or aluminum.

One of the standout features of FRP grating is its excellent resistance to corrosion and chemicals, making it ideal for industries that require a robust flooring solution in harsh environments. According to a recent analysis by Market Research Future, up to 75% of industrial facilities experience at least one form of corrosion-related downtime annually. FRP grating can mitigate this risk significantly, with a lifespan that exceeds 20 years under normal conditions. Additionally, the slip-resistant surface of FRP grating enhances safety in the workplace—a critical consideration as reported incidents can result in costly legal and insurance claims that impact bottom lines.

Moreover, FRP grating is often customizable, allowing industries to tailor the product for specific applications. It can be produced in various colors and sizes, which not only improves the aesthetic appeal of industrial spaces but also contributes to better visibility and safety measures. This adaptability, coupled with its other favorable characteristics, positions FRP grating as an essential solution for the future of industrial flooring and platforms in 2025 and beyond.

Comparative Analysis of Cost-Effective FRP Grating Solutions

When evaluating the best FRP grating solutions for industrial applications, cost-effectiveness is a primary concern for businesses. FRP (Fiberglass Reinforced Plastic) grating provides a vast array of solutions that combine durability with affordability. Key factors to consider in your comparative analysis should include the initial cost of materials, long-term maintenance needs, and the lifespan of the grating. By understanding these elements, companies can make informed decisions that optimize their investments while ensuring safety and efficiency in operations.

Tips for selecting FRP grating include focusing on the specific environmental conditions of your application. For instance, certain FRP formulations are more resistant to chemicals or UV exposure, which can significantly extend their lifespan. Additionally, consider the weight-bearing capacity required for your application; choosing the right thickness and mesh pattern can greatly influence both performance and cost. Finally, look into the supplier's reputation and product warranties, as these can affect long-term cost-effectiveness and reliability.

Understanding different types of FRP grating, such as molded vs. pultruded grating, also plays a critical role in your analysis. While molded grating tends to be less expensive upfront, pultruded grating may offer superior strength and longevity, making it a better investment in high-load areas. Comparing options based on both initial costs and their performance over time can lead to optimal choices in grating solutions tailored for your specific industrial needs.

Innovative Applications of FRP Grating in Industrial Settings

In recent years, the industrial sector has increasingly turned to innovative solutions such as fiberglass reinforced plastic (FRP) grating for various applications. These solutions offer enhanced durability and cost-effectiveness, allowing industries to improve equipment lifespan while reducing operational expenses. One standout manufacturer in this field, known for exceptional quality, has solidified its reputation for producing FRP industrial products that meet the rigorous demands of modern manufacturing.

The versatility of FRP grating is evident in its wide range of applications across different industrial settings. For instance, in environments where traditional materials may falter due to corrosion or heavy loads, FRP grating provides a reliable alternative. Its lightweight yet strong structure not only enhances safety but also reduces the need for extensive maintenance, translating into significant cost savings. As the global demand for sustainable and resilient materials continues to grow, the adoption of advanced FRP solutions is likely to expand further, affirming their role as a cornerstone in the evolution of industrial manufacturing practices.

Maintenance Tips for Maximizing the Lifespan of FRP Grating

When it comes to maximizing the lifespan of Fiber Reinforced Plastic (FRP) grating, regular maintenance is crucial. One effective tip is to conduct routine inspections for any signs of wear or damage. Look for cracks, chips, or discoloration that might indicate UV degradation or mechanical stress. Identifying these issues early can prevent more severe damage and extend the life of your grating.

Additionally, keeping the FRP grating clean is essential. Regularly removing debris and contaminants will help avoid abrasive wear and maintain the grating's slip resistance. Using mild detergents and water for cleaning is recommended, avoiding harsh chemicals that can degrade the material’s integrity. Furthermore, addressing spills immediately and ensuring proper drainage can significantly enhance the longevity of the FRP grating.

Lastly, consider applying a protective coating specifically designed for FRP materials. This coating can provide an extra layer of defense against environmental factors and prolong the life of the grating, making it a wise investment for industrial applications. By following these maintenance tips, facility managers can ensure that their FRP solutions remain durable and cost-effective for years to come.

10 Best FRP Grating Solutions for Durable and Cost-Effective Industrial Applications

| Solution Name | Material Type | Load Capacity (lbs/sq ft) | Corrosion Resistance | Cost ($/sq ft) | Maintenance Tips |

|---|---|---|---|---|---|

| Lightweight FRP Grating | Polyester | 125 | High | 10 | Regular cleaning and inspect for wear |

| Anti-Slip FRP Grating | Vinyl Ester | 150 | Very High | 15 | Avoid heavy impact and check for cracks |

| Heavy-Duty FRP Grating | Phenolic | 200 | Excellent | 20 | Inspect regularly for signs of deterioration |

| Chemical Resistant FRP Grating | Epoxy | 175 | Exceptional | 18 | Remove spills immediately and clean thoroughly |

| Lightweight Walkway Grating | Polymer | 100 | Good | 8 | Check for loose fittings regularly |

Future Trends in FRP Grating Technology for Industrial Applications

As industries continue to evolve, the demand for innovative materials in construction and maintenance processes has intensified. Fiber Reinforced Polymer (FRP) grating technology stands at the forefront of this shift, presenting enhanced durability and cost-effectiveness. Future trends indicate a significant focus on sustainability, with manufacturers increasingly integrating recycled materials in FRP production. This move not only reduces environmental impact but also promotes a circular economy, aligning with global sustainability goals.

Additionally, advancements in manufacturing processes are expected to improve the performance and longevity of FRP grating solutions. Innovations such as automated pultrusion and advanced resin formulations will likely enhance the strength-to-weight ratio of grating products, making them even more suitable for demanding industrial applications. As automation and smart technologies become more prevalent, companies are likely to leverage data analytics to optimize the selection and use of FRP grating, ensuring that it meets the specific needs of various operational environments while maintaining cost efficiency.

10 Best FRP Grating Solutions for Durable and Cost-Effective Industrial Applications

Related Posts

-

Top 10 Benefits of Using Stainless Steel Perforated Sheet in Your Projects

-

Exploring the Versatility of Perforated Steel Sheets in Modern Architecture and Design

-

Understanding the Benefits of Aluminum Grating in Modern Construction Designs

-

Understanding the Versatility of Perforated Sheets: Applications and Benefits in Modern Design

-

Understanding Expanded Metal: The Versatile Material Transforming Modern Architecture and Design

-

Exploring the Evolution of Metal Wire: From Ancient Craftsmanship to Modern Engineering Applications