Cart

10 Best Woven Wire Mesh Options for Every Application?

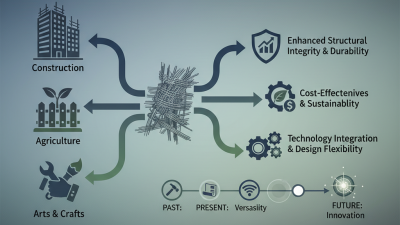

Woven wire mesh is a versatile material used across various industries. Its applications range from construction to filtration. According to a report by Grand View Research, the global wire mesh market is projected to reach $10.59 billion by 2027. This indicates a growing demand for woven wire mesh, driven by innovations in technology and manufacturing processes.

In construction, woven wire mesh provides structural support. It ensures safety and integrity in buildings and bridges. For filtration, it plays a crucial role in separating solids from liquids. However, not all woven wire mesh is created equal. Quality and specifications vary significantly. Identifying the right type is essential for performance. Some options may not meet specific needs, leading to inefficiencies and potential failures.

Choosing the best woven wire mesh requires careful consideration. Factors include wire diameter, mesh size, and material type. A poorly chosen mesh can lead to issues, such as clogging or inadequate support. In this article, we will explore ten top woven wire mesh options suitable for diverse applications. Each option will be examined to highlight its strengths and weaknesses. Understanding these aspects is crucial for making informed decisions in your projects.

Overview of Woven Wire Mesh and Its Applications

Woven wire mesh is a versatile material widely used across various industries. Its design allows for airflow and visibility while providing durability and strength. Common applications include construction, filtration, and even decorative elements. Reports suggest that the industrial wire mesh market is expected to grow significantly, driven by the rising demand in sectors like agriculture and mining.

Different woven wire mesh styles cater to specific needs. For instance, in construction, sturdy options provide safety and security. In filtration applications, mesh with finer openings can effectively separate particles while maintaining high flow rates. Interestingly, reports indicate that incorrect mesh selection can lead to inefficiencies. Many users underestimate how vital the right choice is for product performance.

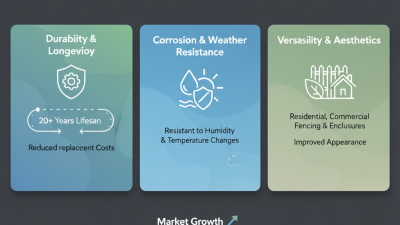

Some challenges exist with woven wire mesh. For example, corrosion can compromise its lifespan. Not all materials offer the same durability against environmental factors. Industry data highlights that over 30% of mesh failures are linked to environmental wear. A better understanding of material properties is essential for optimizing performance. Investing time in this knowledge can lead to improved outcomes and longevity in applications.

10 Best Woven Wire Mesh Options for Every Application

Types of Woven Wire Mesh Materials and Their Properties

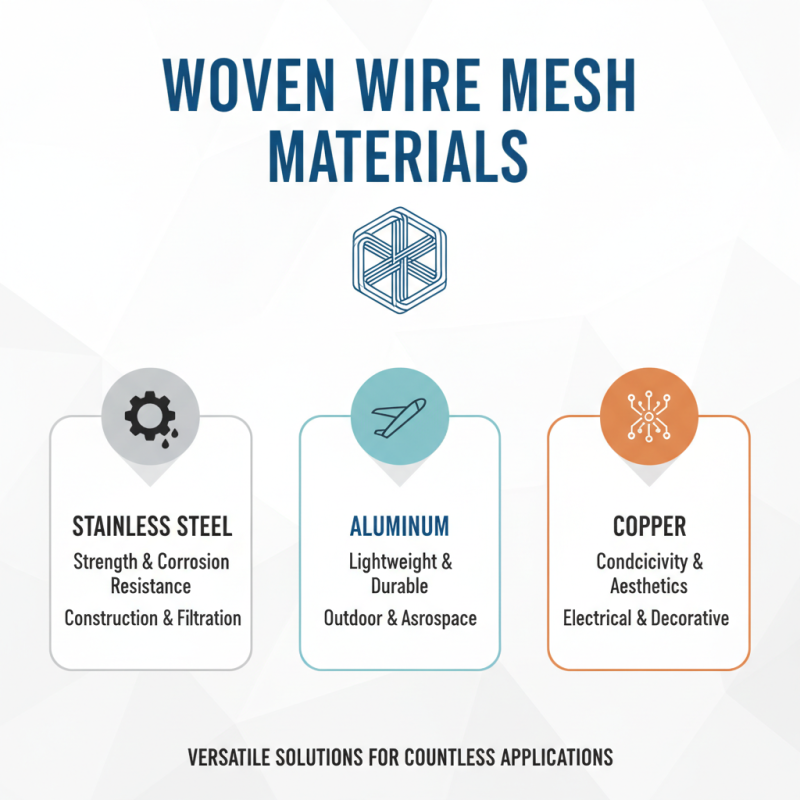

Woven wire mesh materials provide a versatile solution across many applications. Common types include stainless steel, aluminum, and copper. Stainless steel is popular for its strength and resistance to corrosion. It is often used in construction and filtration systems. Aluminum offers lightweight properties, making it ideal for applications where weight is a concern. Its corrosion resistance also adds to its appeal for outdoor use.

Copper mesh is another option, known for its antimicrobial properties. This makes it useful in medical and food-related applications. While these materials have distinct benefits, there are trade-offs. For example, stainless steel can be heavy and expensive. Aluminum may not provide the same structural integrity in high-stress environments. Each type of woven wire mesh has unique characteristics that can impact performance. Carefully consider your needs before choosing a material.

Factors to Consider When Choosing Woven Wire Mesh

When selecting woven wire mesh, several factors come into play. The material is crucial. Options like stainless steel, aluminum, or galvanized steel each offer unique benefits. Stainless steel is strong and resistant to corrosion, making it ideal for outdoor applications. Aluminum is lightweight and easy to handle, suitable for many indoor uses.

The mesh pattern also matters. Choices include plain weave, twill weave, or locked weave. Each has different strength and flexibility levels. Consider how you plan to use the mesh. For applications needing high durability, a tighter weave may be essential. But a looser weave can allow for better airflow.

Lastly, don't overlook the mesh’s size and shape. Think about the intended purpose. Will it be used for filtration or as a structural element? Perhaps you need custom-sized sheets. Every detail can impact performance. Reflecting on these aspects will guide your decision, ensuring the mesh meets your specific needs effectively.

Top 10 Woven Wire Mesh Options for Specific Applications

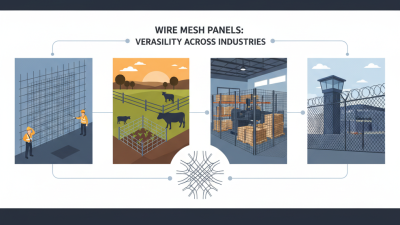

Woven wire mesh is a versatile material widely used across various industries. Each application has unique requirements that influence mesh selection. For example, in the food processing industry, a mesh with a small aperture is essential. It ensures that contaminants are effectively filtered out. Reports indicate that nearly 30% of foodborne illnesses correlate with improper filtration methods.

In the construction sector, welded wire mesh proves invaluable. This mesh provides structural support and maintains shape under stress. Data shows that using welded wire mesh can reduce construction delays by up to 15%. However, improper installation can compromise strength. This poses a concern for safety.

In environmental applications, woven wire mesh helps in erosion control and sediment filtration. A mesh designed for this purpose often features larger openings, allowing water flow but capturing larger particles. Yet, it's critical to regularly check for clogging. Routine maintenance is often neglected, leading to decreased effectiveness. A proactive approach is necessary to ensure optimal performance in each application.

Maintenance and Care Tips for Woven Wire Mesh Products

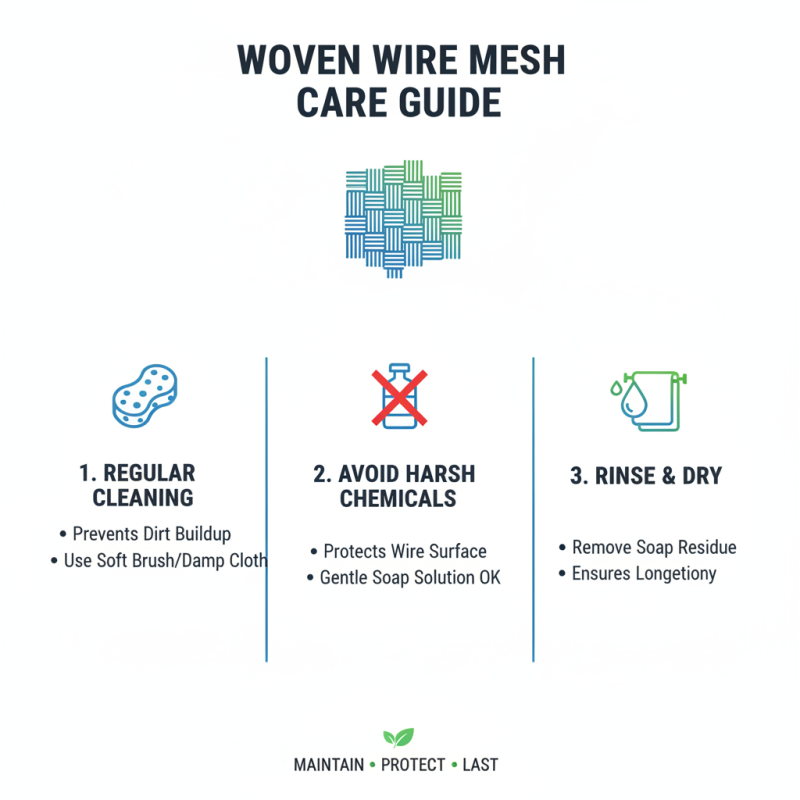

Woven wire mesh products require consistent maintenance to ensure longevity. Regular cleaning helps prevent dirt buildup. Use a soft brush or damp cloth for basic cleaning. Avoid harsh chemicals that could damage the wire's surface. For deeper cleaning, consider using a gentle soap solution. Rinse well to remove any soap residue.

Inspect your woven wire mesh periodically. Look for rust or signs of wear. If you notice any damage, address it promptly. This can prevent larger issues from developing. In humid environments, additional protective measures may be necessary. A rust-inhibiting spray can be quite effective for maintenance. Always follow the manufacturer’s recommendations for care.

Functional yet aesthetically appealing, woven wire mesh can be a challenge without proper attention. Remember, neglecting maintenance can lead to performance issues. It’s not just about cleaning; it's about enhancing its lifespan. Small issues, if left unchecked, may escalate. Reflect on your care routine and adjust as needed for the best outcomes.

Related Posts

-

What is Wire Mesh Panels and How Are They Used in Various Industries

-

2025 Top Uses of Steel Wire Mesh: Applications, Benefits, and Trends

-

2025 Guide: How to Choose the Right Wire Mesh Screen for Your Project

-

Top 10 Benefits of Wire Mesh Screens for Home and Industrial Use

-

Top Benefits of Using PVC Coated Wire Mesh for Your Projects

-

Top 5 Benefits of Using Metal Mesh for Your Home and Office Needs