Cart

How to Choose the Right Stainless Steel Wire Mesh for Your Project

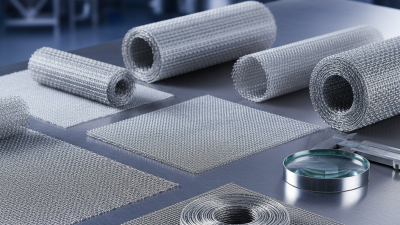

Selecting the appropriate stainless steel wire mesh for your project is crucial for ensuring functionality, durability, and success. This versatile material has multiple applications, ranging from construction and industrial use to decorative and filtration solutions. However, the sheer variety of stainless steel wire mesh options available can make this decision overwhelming. Understanding the key factors that influence your choice can help steer you towards the right product that meets your specific requirements.

When considering stainless steel wire mesh, it's essential to evaluate several critical aspects, such as the mesh's specifications, including wire diameter, opening size, and material grade. These elements not only affect the mesh's strength and flexibility but also its suitability for different environments and purposes. Additionally, factors like corrosion resistance and the intended application play a significant role in determining which type of stainless steel wire mesh will provide the best performance and longevity for your project. Through careful consideration of these factors, you can confidently select the right stainless steel wire mesh that aligns with your needs and ensures the success of your undertaking.

Understanding Stainless Steel Grades and Their Applications

When selecting the appropriate stainless steel wire mesh for your project, understanding the different grades of stainless steel is crucial as they greatly influence performance and application suitability. The most common grades include 304 and 316. Grade 304 offers excellent corrosion resistance and is commonly used in applications such as food processing and interior environments. In contrast, grade 316 is preferred for marine and chemical settings due to its added molybdenum content, which offers superior resistance to chlorides and acids.

Tips: When selecting stainless steel wire mesh, assess the environmental factors it will be exposed to. For instance, if your project is close to saltwater or involves exposure to chemicals, opt for grade 316 for enhanced durability. Additionally, consider the wire diameter and openness of the mesh; these can significantly affect strength and airflow, depending on your specific needs.

Furthermore, each grade has its own set of properties that cater to specific applications. For filtering and sieving, a finer mesh might be necessary, while heavier applications may require sturdier, thicker wire. It's also important to evaluate the intended use, as aesthetic requirements can play a role in your choice of wire mesh. Always prioritize performance attributes like tensile strength and resistance to wear for optimal results.

How to Choose the Right Stainless Steel Wire Mesh for Your Project

This chart illustrates the tensile strength of various stainless steel grades commonly used in wire mesh applications. Materials such as 304 and 316 stainless steel offer higher tensile strengths, making them suitable for more demanding environments compared to 430 and 201 grades.

Key Considerations for Choosing Wire Diameter and Mesh Size

When selecting stainless steel wire mesh for a project, understanding the interplay between wire diameter and mesh size is crucial. The wire diameter directly influences the strength and durability of the mesh. Typically, a thicker wire diameter results in a more robust mesh that can withstand greater tension and pressure, making it ideal for applications requiring enhanced load-bearing capabilities. According to industry reports, wire diameters can range from 0.1 mm to over 10 mm, with applications often dictating the appropriate choice. For example, construction and industrial settings often default to heavier wires to ensure longevity under challenging environments.

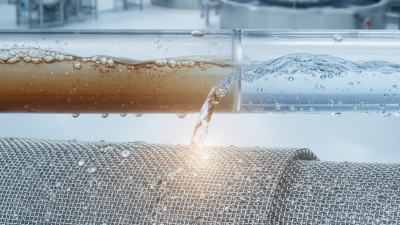

Mesh size, on the other hand, refers to the number of openings per inch or the size of the openings themselves. The optimal mesh size must align with the specific needs of your project, such as filtration or safety. Research has indicated that finer mesh sizes—with more openings—are crucial for applications like water filtration or pest control, as they can effectively prevent unwanted particles while allowing fluid flow. Conversely, a coarser mesh size might be requested in contexts such as security fencing where visibility and airflow are desired without compromising structural integrity. Industry standards suggest that choosing the correct combination of wire diameter and mesh size can enhance project efficiency and ensure material performance, contributing to overall project success.

Identifying Optimal Opening Types for Specific Projects

When selecting the right stainless steel wire mesh for your project, understanding the optimal opening types is crucial. Different applications require specific mesh sizes and configurations to achieve desired functionality. For example, a finer mesh with smaller openings is ideal for filtration projects, as it effectively traps particles while allowing liquids to pass through. Conversely, if you are looking to provide structural support or create barriers, a coarser mesh with larger openings may be more suitable. It is important to consider what you need to filter or protect against when making your selection.

**Tips:**

When determining the appropriate opening type, it's helpful to start with the project’s primary objective. If you're working on a decorative screen, for instance, aesthetics may play a larger role in your choice than functionality. Similarly, in agricultural applications, consider which insects or debris need to be kept out. Always assess the environmental conditions the mesh will face, such as exposure to moisture or chemicals, and ensure the selected mesh can withstand these factors without degrading over time.

Another aspect to consider is the wire diameter in relation to the mesh opening size. Thicker wires provide additional strength, which is essential for heavy-duty applications, while finer wires may be suitable for lighter, more delicate tasks. Balancing these parameters can lead to significant benefits in durability and performance, ensuring your project is both effective and long-lasting.

How to Choose the Right Stainless Steel Wire Mesh for Your Project - Identifying Optimal Opening Types for Specific Projects

| Mesh Type | Aperture Size (inches) | Wire Diameter (gauge) | Material Type | Typical Applications |

|---|---|---|---|---|

| Woven Wire Mesh | 1/4 | 23 | 304 Stainless Steel | Filtration, sieving |

| welded Wire Mesh | 1/2 | 16 | 316 Stainless Steel | Construction, security |

| Expanded Metal Mesh | 1/8 x 1/4 | 12 | 304 Stainless Steel | Fencing, walkways |

| Perforated Metal Mesh | 3/16 | 12 | 316 Stainless Steel | Architectural, decorative screens |

| Bar Grating | 1 x 1 | 1/4 | 304 Stainless Steel | Walkways, drainage |

Evaluating Corrosion Resistance and Durability in Wire Mesh

Choosing the right stainless steel wire mesh for your project involves critical evaluation of its corrosion resistance and durability. Stainless steel is generally known for its ability to withstand harsh environmental conditions, but not all grades offer the same level of protection.

For instance, the Composite Material Handbook 17 highlights that wire meshes made from 304 stainless steel exhibit moderate corrosion resistance, while 316 stainless steel provides superior protection due to the addition of molybdenum, making it preferable for marine and chemical applications.

Tip: Consider environmental factors when selecting your wire mesh. If your project is exposed to saltwater or corrosive chemicals, opting for 316 stainless steel will significantly enhance the longevity of your mesh, ensuring it retains its structural integrity over time.

Durability is another crucial aspect to contemplate. The American Society for Testing and Materials (ASTM) indicates that the tensile strength and overall resilience against wear and tear can vary between wire mesh types. For rigorous industrial applications, such as filtration processes or heavy-duty fencing, a higher wire gauge can improve durability and resistance to deformation.

Tip: Perform a tensile strength test if you're unsure about your mesh's capabilities. This simple assessment can inform you about potential failure points, helping you choose a wire mesh that meets both structural and safety requirements for your specific application.

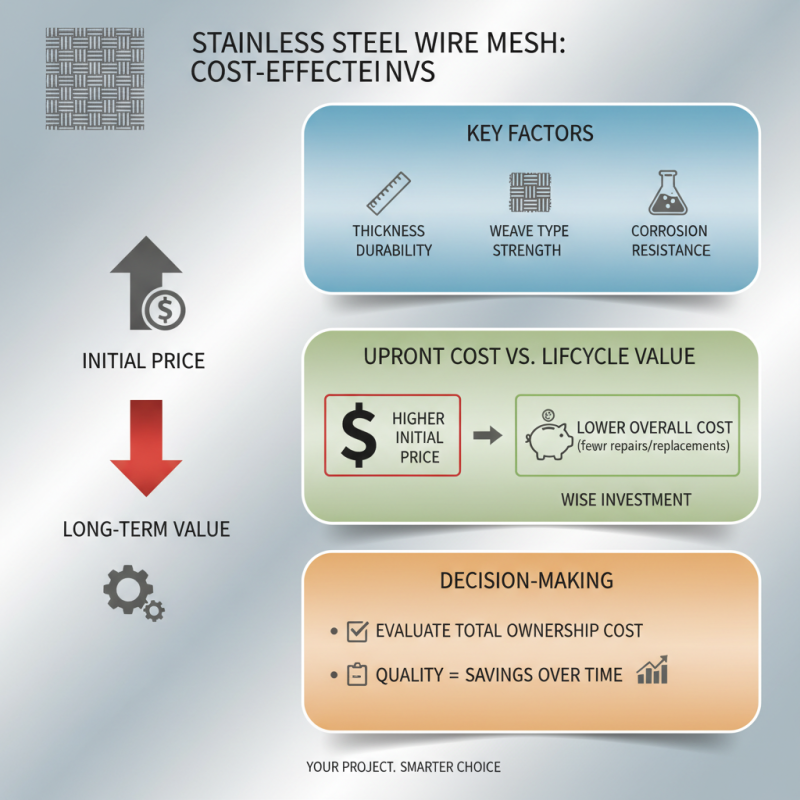

Assessing Cost-Effectiveness and Supplier Reliability in Sourcing

When sourcing stainless steel wire mesh for your project, the cost-effectiveness of various options plays a crucial role in decision-making. It's essential to evaluate not only the initial price of the wire mesh but also its long-term value. Consider factors such as thickness, weave type, and corrosion resistance, as these elements can significantly influence durability and maintenance costs over time. A more expensive, high-quality wire mesh may save you money in repairs and replacements in the future, making it a wise investment despite a higher upfront cost.

Equally important is the reliability of your suppliers. A trustworthy supplier can provide consistent quality, timely delivery, and responsive customer service, which are vital for the success of your project. Check for certifications, customer testimonials, and their experience in the industry. Building a relationship with a dependable supplier can lead to better negotiation terms and insights into upcoming trends or innovations in stainless steel wire mesh. Thus, balancing cost-effectiveness with supplier reliability is key to ensuring that your project runs smoothly and achieves its intended outcomes.

Related Posts

-

Why Stainless Steel Mesh is the Best Choice for Your Filtration Needs

-

Top 10 Tips for Choosing the Right Stainless Steel Mesh for Your Needs

-

Exploring the Evolution of Metal Wire: From Ancient Craftsmanship to Modern Engineering Applications

-

How to Choose the Right Metal Grate for Your Outdoor Project

-

Exploring the Versatility of Perforated Steel Sheets in Modern Architecture and Design

-

Top 10 Aluminum Stair Treads for Safety and Durability