Cart

Top 10 Tips for Choosing the Right Steel Wire Mesh for Your Projects

In the world of construction and manufacturing, choosing the right materials can significantly impact the success of any project. When it comes to ensuring durability and strength, steel wire mesh stands out as a vital component. As industry expert John Doe, a renowned structural engineer, points out, “The quality of your steel wire mesh can be the difference between a solid foundation and a disaster waiting to happen.” With numerous options available, selecting the appropriate steel wire mesh requires careful consideration of various factors, from wire thickness to mesh size.

This article aims to provide essential tips for making informed choices about steel wire mesh for your projects. Understanding the specific requirements of your application, including load capacity and environmental conditions, is crucial. Moreover, factors such as corrosion resistance and ease of installation should also influence your decision. By synthesizing expert advice and practical insights, we will guide you through the process of selecting the best steel wire mesh to meet your project needs effectively. Prepare to equip yourself with the knowledge that sets your projects on a path to success.

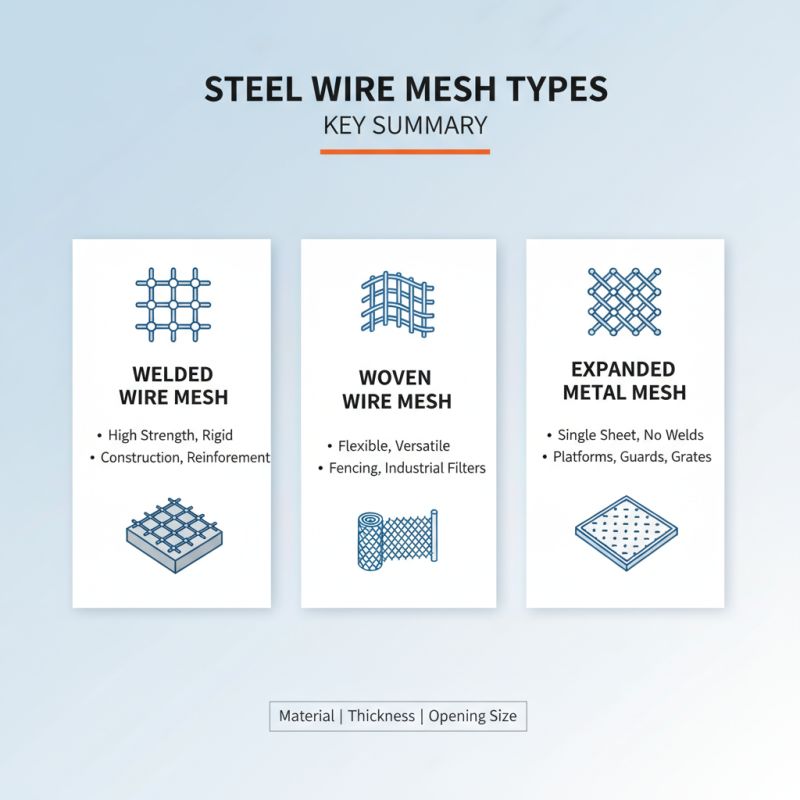

Understanding Different Types of Steel Wire Mesh Available on the Market

When selecting steel wire mesh for your projects, it's crucial to understand the various types available in the market. Steel wire mesh is typically categorized by its material, wire thickness, and the size of openings. Common types include welded wire mesh, woven wire mesh, and expanded metal mesh. Each type serves different purposes; for instance, welded wire mesh offers greater strength and rigidity, making it ideal for construction and reinforcement applications. In contrast, woven wire mesh is more flexible and is often used in industrial settings or for fencing.

Consider the specific requirements of your project when choosing the right type of steel wire mesh. For structural support, opt for heavier gauge materials that can withstand significant loads. Conversely, if you need a barrier or a decorative feature, lighter and more aesthetically designed mesh might be more appropriate.

One key tip is to evaluate the environmental conditions the mesh will face. If the mesh is exposed to moisture or corrosive elements, selecting galvanized or stainless steel options can enhance durability. Additionally, always double-check the mesh's certification standards to ensure it meets the necessary safety and quality requirements for your intended use.

Assessing Project Requirements: Load, Size, and Durability Considerations

When choosing the right steel wire mesh for your projects, it is crucial to assess project requirements carefully, focusing on load, size, and durability considerations. The load-bearing capacity of the wire mesh is a fundamental factor; it must be suitable for the materials it will support. Different applications, such as construction, fencing, or reinforcement, require specific load ratings to ensure safety and effectiveness. Understanding the anticipated weights and stresses the mesh will encounter during its use is essential for making the appropriate selection.

Size is another key consideration in the process of choosing steel wire mesh. This includes both the dimensions of the mesh sheets and the spacing of the wires or bars. The size must align with the project's design specifications and available space, ensuring that the mesh can be incorporated seamlessly without compromising structural integrity. It's also important to consider the dimensions in relation to the intended use—wider spacing may be suitable for lighter applications, while tighter spacing will be necessary for stronger reinforcement in heavier loads.

Durability plays a significant role in the decision-making process as well. Steel wire mesh is subject to various environmental factors that could affect its lifespan and performance. For projects exposed to moisture, chemicals, or extreme temperatures, selecting a mesh that offers resistance to corrosion and other forms of deterioration will enhance longevity. Evaluating these aspects will ensure that the chosen steel wire mesh not only meets the immediate project needs but also stands the test of time in its operational environment.

Top 10 Tips for Choosing the Right Steel Wire Mesh for Your Projects

| Tip Number | Consideration | Details |

|---|---|---|

| 1 | Load Requirement | Assess the maximum load your project will need to handle. |

| 2 | Mesh Size | Determine the appropriate mesh size based on the project specifications. |

| 3 | Durability | Consider the environmental factors that could affect the wire mesh. |

| 4 | Material | Choose the right type of steel based on corrosion resistance and strength requirements. |

| 5 | Application Type | Identify if the mesh will be used for fencing, flooring, or reinforcement. |

| 6 | Regulatory Standards | Ensure compliance with local building codes and standards. |

| 7 | Cost | Evaluate cost-effectiveness while meeting quality standards. |

| 8 | Availability | Check local suppliers for availability of the required mesh size and type. |

| 9 | Installation Requirements | Understand the installation process and tools needed for your mesh. |

| 10 | Long-term Maintenance | Plan for regular inspections and maintenance to extend the life of the mesh. |

Exploring Coating Options: Galvanized vs. Stainless Steel Wire Mesh

When it comes to selecting the right steel wire mesh for your projects, one of the most crucial decisions revolves around the coating options available, primarily galvanized and stainless steel wire mesh. Galvanized wire mesh is coated in zinc to enhance its resistance to rust and corrosion, making it an excellent choice for outdoor applications or areas exposed to moisture. The process of galvanization not only offers a protective layer but also provides a durable finish that can withstand various environmental conditions. This makes galvanized wire mesh ideal for agricultural, construction, and industrial projects where longevity is essential.

On the other hand, stainless steel wire mesh is inherently resistant to corrosion and tarnishing due to its alloy composition, which includes nickel and chromium. This type of mesh is particularly beneficial in more corrosive environments, such as chemical processing industries or areas with extreme temperatures. While generally more expensive than galvanized options, stainless steel wire mesh offers superior strength and longevity, making it a worthwhile investment for long-term projects. Ultimately, the choice between galvanized and stainless steel wire mesh should be guided by the specific environmental conditions and durability requirements of your project.

Comparison of Coating Options for Steel Wire Mesh

This chart demonstrates the performance comparison between galvanized and stainless steel wire mesh across various project factors.

Evaluating Mesh Aperture and Wire Diameter for Specific Applications

When selecting the appropriate steel wire mesh for your project, two critical factors to evaluate are mesh aperture and wire diameter, as these elements directly impact the performance and suitability of the mesh for specific applications.

The mesh aperture refers to the size of the openings between the wires, which can greatly influence the type of materials that can pass through or be retained. For instance, larger apertures may be ideal for projects requiring drainage or filtration, allowing water and small particles to pass efficiently while keeping larger debris out. Conversely, a finer mesh with smaller apertures is preferable in applications where containment is crucial, such as in animal enclosures or protective barriers.

Wire diameter is another essential consideration, as it determines the strength and durability of the mesh. A thicker wire diameter typically translates to a more robust mesh that can withstand greater tensile forces and resist deformation. This is particularly important in high-stress environments, where the mesh might be subjected to heavy loads or significant impact. However, a thicker wire can also mean reduced flexibility and increased weight, which may not be suitable for all applications.

Therefore, it is crucial to balance mesh aperture and wire diameter, ensuring that the chosen specifications align with the specific needs of your project while maintaining optimal functionality and safety.

Budgeting for Quality: Balancing Cost and Performance in Steel Wire Mesh

When embarking on a project that requires steel wire mesh, understanding how to balance cost and performance is essential. While it might be tempting to opt for the cheapest option available to adhere to budget constraints, it is crucial to remember that quality often correlates with performance in the long term. Lower-cost materials may save you money upfront but can lead to increased expenses later due to frequent replacements or repairs. Assessing the durability and specifications required for your specific application will help ensure that you choose a product that meets your needs without compromising on quality.

To effectively budget for steel wire mesh, start by defining your project requirements. Consider factors such as the mesh size, gauge, and the environment in which it will be used, as these all influence the performance and longevity of the material. Conducting a cost-benefit analysis can reveal whether a higher initial investment in superior quality materials could save costs over time. Additionally, seeking expert advice or consulting specifications can aid in making informed decisions that align with both financial constraints and project goals. Balancing these elements will ensure optimal results while maintaining fiscal responsibility.

Related Posts

-

2025 Top Trends in Metal Mesh Sheet Innovation for Industrial Applications

-

Top 5 Benefits of Using Metal Mesh for Your Home and Office Needs

-

Exploring the Versatility of Perforated Steel Sheets in Modern Architecture and Design

-

Top 10 Benefits of Using Stainless Steel Perforated Sheet in Your Projects

-

How to Choose the Best Steel Stair Treads for Safety and Durability

-

How to Choose the Right Stainless Steel Wire Mesh for Your Project