Cart

10 Essential Tips for Choosing Plastic Grating for Your Project

In the ever-evolving landscape of construction and industrial projects, the significance of choosing the right materials cannot be overstated. Among these materials, plastic grating has emerged as a popular and durable choice for various applications, from flooring to drainage systems. According to a recent report by MarketsandMarkets, the plastic grating market is projected to reach USD 2.8 billion by 2025, growing at a CAGR of 5.2% from 2020. This growth can be attributed to the increasing demand for lightweight, corrosion-resistant solutions that plastic grating offers, particularly in sectors such as construction, industrial, and municipal projects.

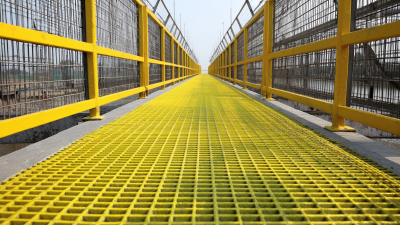

As project managers and engineers strive to meet specific functional and aesthetic requirements, understanding the key factors in selecting plastic grating becomes essential. The versatility of plastic grating allows it to accommodate numerous environments, from wet and corrosive settings to high-traffic areas. However, with the myriad of options available, making an informed choice is crucial for maximizing performance and longevity. This article presents ten essential tips on selecting the right plastic grating for your project, ensuring it aligns with project specifications while providing a safe and efficient solution.

Choosing the Right Type of Plastic Grating: Key Considerations

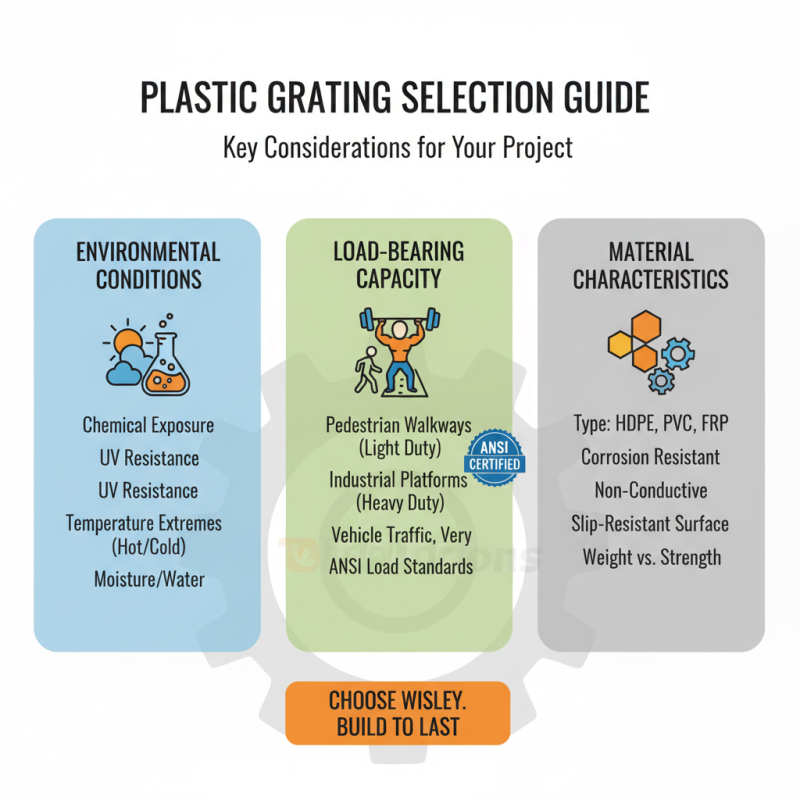

When selecting plastic grating for your project, understanding the various types and their applications is crucial. Key considerations include the environmental conditions in which the grating will be used, load-bearing capacity, and the specific characteristics of the material itself. According to a report by the American National Standards Institute (ANSI), ensuring that the grating meets the appropriate load requirements is vital; for instance, a lightweight option may suffice for pedestrian walkways, while heavier industrial areas may necessitate more robust solutions with a high load-bearing capacity.

Additionally, resistance to chemicals, UV exposure, and thermal fluctuations are other important factors to weigh. A study published by the Composite Materials Handbook indicates that different plastic materials can offer varying degrees of resistance; for example, certain types of fiberglass-reinforced plastic grating are particularly effective in corrosive environments, boasting resistance ratings that can exceed 40% longer lifespan compared to traditional materials. Selecting the right type of plastic grating not only enhances the safety and functionality of your project but can also result in long-term cost efficiencies due to reduced maintenance and replacement needs.

Evaluating Load-Bearing Capacities for Different Plastic Gratings

When selecting plastic grating for a project, evaluating load-bearing capacities is crucial for ensuring safety and functionality. Different types of plastic gratings exhibit varying characteristics that affect their strength and durability. Factors such as the material composition, the panel thickness, and the manufacturing process play significant roles in determining the load they can handle. It's vital to assess these parameters based on the specific requirements of your project, whether for flooring, walkways, or support structures.

Additionally, considering environmental factors is essential when evaluating load-bearing capacities. Plastic gratings may be used in areas exposed to extreme weather conditions, UV radiation, or corrosive substances. Understanding how these elements can impact the integrity of the material over time will help you choose a grating that maintains its load-bearing capability even in challenging environments. Always refer to the manufacturer's technical data sheets to make informed decisions regarding the maximum load limits and the appropriate applications of various plastic grating options.

Understanding Chemical Resistance Ratings for Plastic Grating Materials

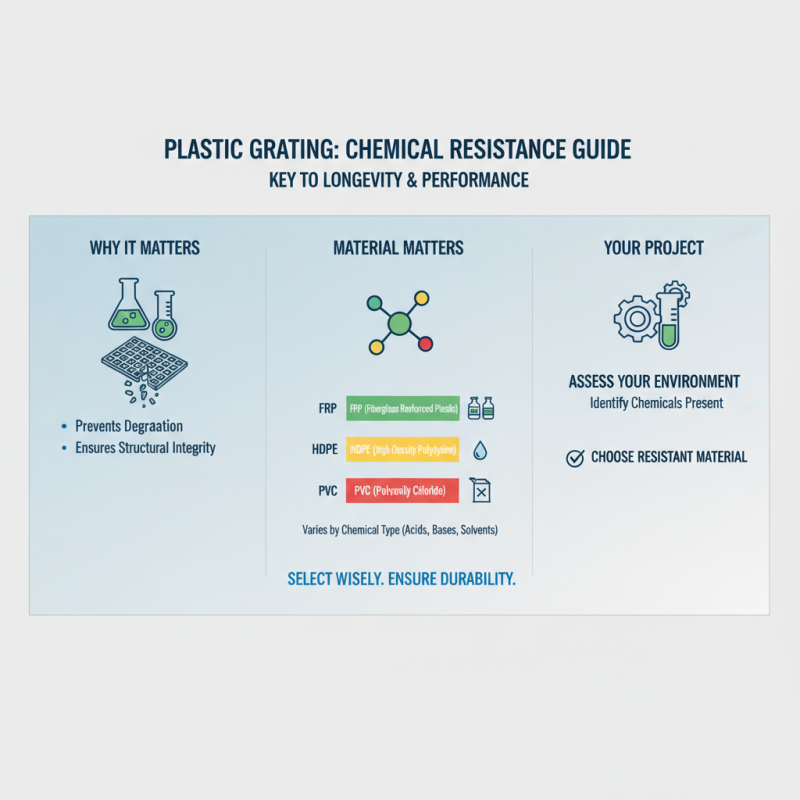

When selecting plastic grating for your project, understanding the chemical resistance ratings of the materials is crucial. Different plastic materials exhibit varying levels of resistance to chemicals, which can significantly affect the longevity and performance of the grating in specific environments. For instance, while some plastic gratings may withstand acids and bases, others might degrade rapidly when exposed to certain solvents. Therefore, it's essential to assess the chemicals your project will encounter and choose a material that can endure those conditions without compromising structural integrity.

Chemical resistance ratings typically categorize materials based on their ability to resist particular substances. These ratings are often derived from standardized testing methods that provide a comparative overview of how different plastics react when exposed to various chemicals. When evaluating plastic grating options, make sure to consult these ratings and look for any additional information on the manufacturer's testing methods. This due diligence will help ensure that the selected grating not only fits the physical demands of the project but also meets the chemical requirements necessary for safe and effective operation over time.

Assessing Environmental Impact and Sustainability of Grating Options

When selecting plastic grating for a project, it’s crucial to assess not only its functional properties but also its environmental impact and sustainability. Many plastic grating options are derived from materials that can be less eco-friendly due to their manufacturing processes and lifecycle. Organizations should seek products made from recycled materials, as this can significantly reduce the carbon footprint associated with production. Additionally, opting for grating systems that are designed for longevity can minimize waste over time, ensuring that fewer materials end up in landfills.

Moreover, the choice of plastic grating can influence energy consumption. Some products are designed to be lightweight yet durable, which can lead to lower transportation emissions during distribution. It’s essential to consider the end-of-life strategy for the plastic grating being used. Gratings that are recyclable or can be repurposed at the end of their lifespan support a circular economy, further enhancing their sustainability profile. By integrating environmental considerations into the decision-making process, project managers can align their choices with broader sustainability goals while ensuring that the grating meets the necessary performance standards.

10 Essential Tips for Choosing Plastic Grating for Your Project - Assessing Environmental Impact and Sustainability of Grating Options

| Tip | Description | Environmental Impact | Sustainability Rating |

|---|---|---|---|

| 1. Material Selection | Choose recycled or eco-friendly materials. | Low impact, promotes recycling. | A |

| 2. Load-Bearing Capacity | Ensure the grating can handle intended loads. | Moderate, depends on usage. | B |

| 3. UV Resistance | Select materials that resist UV degradation. | Reduces lifespan and waste. | A |

| 4. Chemical Resistance | Ensure compatibility with environment chemicals. | Prevents contamination. | B |

| 5. Installation Process | Evaluate ease and speed of installation. | Reduced labor impact. | A |

| 6. Maintenance Requirements | Consider long-term upkeep needs. | Lower maintenance reduces waste. | A |

| 7. Aesthetic Value | Choose designs that enhance visual appeal. | Promotes longer usage. | B |

| 8. Slip Resistance | Evaluate traction to prevent accidents. | Safety reduces environmental impact. | A |

| 9. Cost-Effectiveness | Balance quality with budget requirements. | Smart investment reduces waste. | B |

| 10. Supplier Certification | Choose certified suppliers for quality assurance. | Ensures sustainable practices. | A |

Exploring Cost-Effectiveness and Lifespan of Various Plastic Gratings

When selecting plastic grating for your project, understanding the cost-effectiveness and lifespan of various options is critical. According to industry reports, the average lifespan of fiberglass reinforced plastic (FRP) grating ranges from 15 to 30 years, significantly outpacing traditional materials such as wood or metal, which tend to require more frequent replacements. This durability translates into lower long-term costs despite higher upfront expenses, making FRP an attractive option for projects focused on sustainability and economy.

When considering types, it’s essential to evaluate the specific requirements of your project. For instance, if slip resistance and ease of maintenance are priorities, choosing products with textured surfaces can enhance safety and longevity. Incorporating these guidelines early in the decision-making process ensures the chosen grating aligns with project goals. Additionally, exploring bulk purchasing options or local suppliers can help in minimizing overall costs, thus providing better budget management.

In summary, while individual project needs may vary, focusing on cost-effectiveness and durability can guide your choice of plastic grating. By investigating the various longevity and price point metrics, you can make a more informed decision that benefits both your project budget and operational efficiency.

Cost-Effectiveness and Lifespan of Various Plastic Gratings

Related Posts

-

10 Best FRP Grating Solutions for Durable and Cost-Effective Industrial Applications

-

What is Steel Wire Mesh Its Types Applications and Market Growth Trends

-

How to Choose the Right Stainless Steel Wire Mesh for Your Project

-

Top 5 Benefits of Using Metal Mesh for Your Home and Office Needs

-

2025 Top 10 Decorative Metal Sheets for Stylish Home Decor and Unique Designs

-

Top 10 Aluminum Stair Treads for Safety and Durability