Cart

What is Expanded Metal and How is it Used in Various Industries?

Expanded metal is a versatile material widely used across various industries. It is made by cutting and stretching metal sheets, creating a network of diamond-shaped openings. According to John Smith, an expert in the field, "Expanded metal combines strength and functionality in ways few materials can." This unique structure allows for increased airflow and light penetration while providing durability.

In construction, expanded metal serves as a protective barrier and provides reinforcement in concrete. The automotive industry uses it for lightweight components that maintain strength. Additionally, architectural designs often incorporate expanded metal for aesthetic facades. Each application highlights its adaptability and the balance between form and function.

However, not all possibilities have been explored. Some industries may overlook the potential of expanded metal due to misconceptions about its strength. It is essential to challenge these notions and understand how this material can innovate design and construction. Continued research and development will reveal even more uses for expanded metal in unconventional sectors. Reflecting on its journey, one wonders: are we fully utilizing its potential?

What is Expanded Metal?

Expanded metal is a type of mesh made from sheets of metal. It undergoes a special process where the sheet is cut and stretched. This creates a strong, lightweight product with unique characteristics. The openings in the mesh can vary in size and shape. This versatility makes it suitable for many applications.

In construction, expanded metal provides strong reinforcement. Builders often use it in walls and ceilings. It creates a stable framework. Many industries utilize expanded metal for security. Fences, gates, and barriers benefit from its durability. In the architectural field, designers appreciate its aesthetic appeal. It allows for creative designs while maintaining strength.

Each application requires careful consideration. The decision on mesh size affects strength and appearance. Not every project benefits from expanded metal. Sometimes, other materials are more suitable. Understanding these nuances is essential for optimal use. Expanded metal can offer solutions, but it’s not always the answer.

The Manufacturing Process of Expanded Metal

Expanded metal is created from a flat sheet of metal that is slit and stretched. This process forms a mesh of diamond-shaped openings. The result is a sturdy yet lightweight material that has various applications across industries.

In manufacturing expanded metal, the first step involves selecting the right metal alloy. Steel, aluminum, and other materials can be used. Workers then use specialized machinery to cut and expand the metal sheet. The process requires precision. Each cut must be uniform for optimal strength and performance. Sometimes, the stretching can lead to imperfections. These may not be immediately noticeable but can affect the finished product’s integrity.

Tips for working with expanded metal include ensuring proper ventilation during manufacturing. This helps in managing fumes generated from heating metals. When applying this material in construction, consider the load it needs to bear. Also, keep in mind that while expanded metal is durable, it can be susceptible to corrosion if not treated. This can lead to premature failure. Regular inspections and maintenance can help in identifying issues early on.

Usage of Expanded Metal in Various Industries

Common Applications of Expanded Metal in Construction

Expanded metal is a versatile material widely used in the construction industry. It is produced by cutting and stretching metal sheets, creating intricate patterns. This structure allows for a lightweight yet strong product, ideal for various applications. Expanded metal offers excellent airflow and visibility while maintaining security.

In construction, it often serves as a supportive framework for walls and ceilings. Its design helps reduce weight while providing structural integrity. Expanded metal is also popular for safety mesh in staircases and walkways. This usage is vital for ensuring safety in high-traffic areas.

Many architects also appreciate expanded metal’s aesthetic appeal. It can be used in facades and decorative elements. However, some might find the look too industrial. It can sometimes clash with certain architectural styles. Balancing functionality and design is a challenge that needs careful consideration in projects.

What is Expanded Metal and How is it Used in Various Industries? - Common Applications of Expanded Metal in Construction

| Application | Industry | Description |

|---|---|---|

| Safety Barriers | Construction | Used to create barriers that prevent falls and enhance safety on construction sites. |

| Ventilation Grills | Buildings | Allows for airflow while preventing the entry of larger debris. |

| Walkways and Platforms | Manufacturing | Provides a durable walking surface that is slip-resistant and allows for drainage. |

| Decorative Facades | Architecture | Enhances building aesthetics while providing structural support and light penetration. |

| Support Frames | Construction | Used as a light yet strong framework in various building projects. |

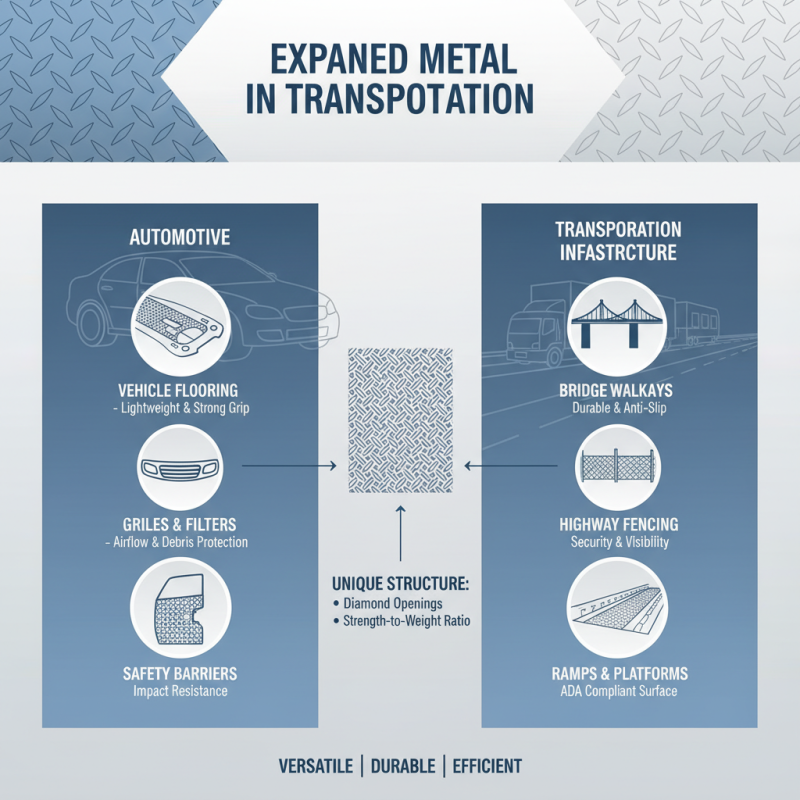

Uses of Expanded Metal in Transportation and Automotive Industries

Expanded metal is a versatile material widely used in transportation and automotive industries. Its unique structure provides strength while remaining lightweight. This makes it ideal for various applications, such as vehicle flooring and safety barriers. The diamond-shaped openings allow for ventilation and reduce overall weight without sacrificing durability.

In transportation, expanded metal is commonly seen in train and bus platforms. Its slip-resistant surface improves safety for passengers. It’s also used in grilles for air intake, ensuring adequate airflow. Automotive manufacturers utilize expanded metal in production as well. Parts like undercarriage shields benefit from its resistance to corrosion and impact.

While expanded metal has many advantages, it’s essential to consider its limitations. The mesh design may not suit every application, especially those requiring solid surfaces. Additionally, the production process can lead to waste if not properly managed. That’s a crucial point for industries aiming for sustainability. Exploring these factors can help optimize its use in future projects.

Benefits of Using Expanded Metal in Various Applications

Expanded metal has gained popularity across various industries due to its unique properties. One significant benefit is its strength-to-weight ratio. Despite being lightweight, expanded metal is highly durable. This makes it an ideal choice for applications where reducing weight is essential. For instance, in construction, it can be used for walkways and safety barriers.

Another advantage of expanded metal is its versatility. It can be easily customized to fit different needs. Industries use it for ventilation and security purposes. In the agricultural sector, it serves as a fencing material. Its open structure allows air and light to pass through while providing security. However, the aesthetic appeal can sometimes fall short, requiring additional finishing.

Cost-effectiveness is also a key benefit. Expanded metal is often more affordable than traditional alternatives. This can result in budget savings for large projects. However, it's important to evaluate its long-term durability. Sometimes, cheaper options may not withstand harsh conditions. Proper consideration is necessary to ensure the right choice is made for specific applications.

Related Posts

-

Understanding Expanded Metal: The Versatile Material Transforming Modern Architecture and Design

-

2025 Top Trends in Metal Mesh Sheet Innovation for Industrial Applications

-

Top 5 Benefits of Using Metal Mesh for Your Home and Office Needs

-

2025 How to Choose the Best Steel Stair Treads for Safety and Durability

-

Exploring the Evolution of Metal Wire: From Ancient Craftsmanship to Modern Engineering Applications

-

What is Steel Wire Mesh Its Types Applications and Market Growth Trends