Cart

What is Expanded Metal Mesh and Its Applications in Various Industries

Expanded metal mesh is a versatile material used across many industries. It is created by cutting and stretching a sheet of metal. This process forms a diamond-shaped pattern, which enhances its strength while maintaining a lightweight profile. According to industry expert Dr. Alice Bennett, "expanded metal mesh combines functionality with aesthetics in diverse applications."

In construction, it serves as a support for plaster, while in the automotive industry, it is used for grills and guards. Its ability to allow airflow makes it essential in ventilation systems. However, some still underestimate its potential. The lack of awareness can limit the adoption of expanded metal mesh in innovative designs.

Applications are diverse, yet not all explore its benefits fully. Some industries still rely on traditional materials without considering the advantages of using expanded metal mesh. Thus, re-evaluating its use could lead to breakthroughs in efficiency and design. Embracing this material requires a shift in perception, highlighting the importance of informed decisions in material selection.

Definition and Characteristics of Expanded Metal Mesh

Expanded metal mesh is a versatile material widely used in various industries. It is created by cutting and stretching a solid sheet of metal. This results in a mesh-like structure that is both strong and lightweight. Its unique characteristics include excellent ventilation, visibility, and anti-slip properties. The open design allows air and light to pass through, making it suitable for applications requiring airflow.

In construction, expanded metal mesh is often used for safety barriers and facades. A report from the Global Construction Market states that the demand for expanded metal mesh has grown significantly, with a projected increase of 6% annually through 2025. This growth reflects the material's ability to withstand heavy loads while remaining lightweight. In the automotive industry, it is utilized for grills and protective screens due to its durability.

However, expanded metal mesh is not without its challenges. The cutting process can lead to sharp edges. Proper handling and installation are crucial to ensure safety. Also, while it is generally resistant to corrosion, the type of coating used can impact its longevity. Choosing the right finish requires careful consideration of environmental factors. Overall, expanded metal mesh demonstrates significant utility across industries, but attention to detail is essential in its application.

Manufacturing Process of Expanded Metal Mesh

Expanded metal mesh is a versatile material widely used across various industries. The manufacturing process of expanded metal mesh begins with a flat sheet of metal. This sheet undergoes a special cutting process, creating diamond-shaped openings. Once cut, the sheet is stretched. This action allows the metal to expand, forming a mesh structure. The final product is strong yet lightweight.

When exploring the manufacturing process, it's crucial to ensure consistent quality. Variations in the sheet's thickness can impact strength and flexibility. Attention to detail during the stretching process is essential. An uneven stretch can result in weak points, affecting the material's durability.

Tips: Always inspect the raw sheets for defects. Look for inconsistencies in thickness and surface quality. A careful evaluation prevents issues later in production. Additionally, consider different metal types. Aluminum, steel, and stainless steel offer unique benefits for diverse applications. Make sure to choose the right material for your intended use.

Common Applications in Construction and Architecture

Expanded metal mesh is a versatile material frequently used in construction and architecture. It consists of sheets of metal that have been cut and stretched to create a mesh pattern. This design allows for excellent airflow while retaining structural integrity. Its unique properties make it an attractive choice for various applications, particularly in modern architecture.

In construction, expanded metal mesh is often used in facades, offering both safety and aesthetics. The mesh allows natural light to filter through while providing security to the building. It can be painted or left in its raw state, offering flexibility in design. When used as walkways, expanded metal mesh provides a slip-resistant surface, essential for safety in outdoor environments.

However, using expanded metal mesh isn’t without challenges. Proper installation requires attention to detail to ensure durability and strength. If not handled correctly, the mesh may warp or fail under pressure. Additionally, its surface can collect debris, necessitating regular maintenance to keep it looking polished. These factors require careful consideration in the design phase to optimize performance and longevity.

Applications of Expanded Metal Mesh in Various Industries

Industrial Uses of Expanded Metal Mesh in Manufacturing

Expanded metal mesh is a versatile material used in various manufacturing sectors. It consists of sheets of metal that are slit and stretched to create a mesh pattern. This design offers strength while being lightweight. Many factories incorporate expanded metal for safety barriers, walkways, and machinery guards.

In the construction industry, expanded metal is often utilized for reinforcing concrete structures. It provides support and enhances durability. Architects appreciate its aesthetic appeal, using it in facades and decorative elements. In the automotive field, expanded metal mesh serves critical functions in both structural elements and ventilation systems.

While expanded metal has many advantages, it is not without its challenges. Proper installation is crucial to prevent issues like warping or rusting. Depending on the environment, the choice of metal type matters greatly. In harsh conditions, some metals may not perform as expected. Continuous evaluation of needs and materials is essential for optimal performance.

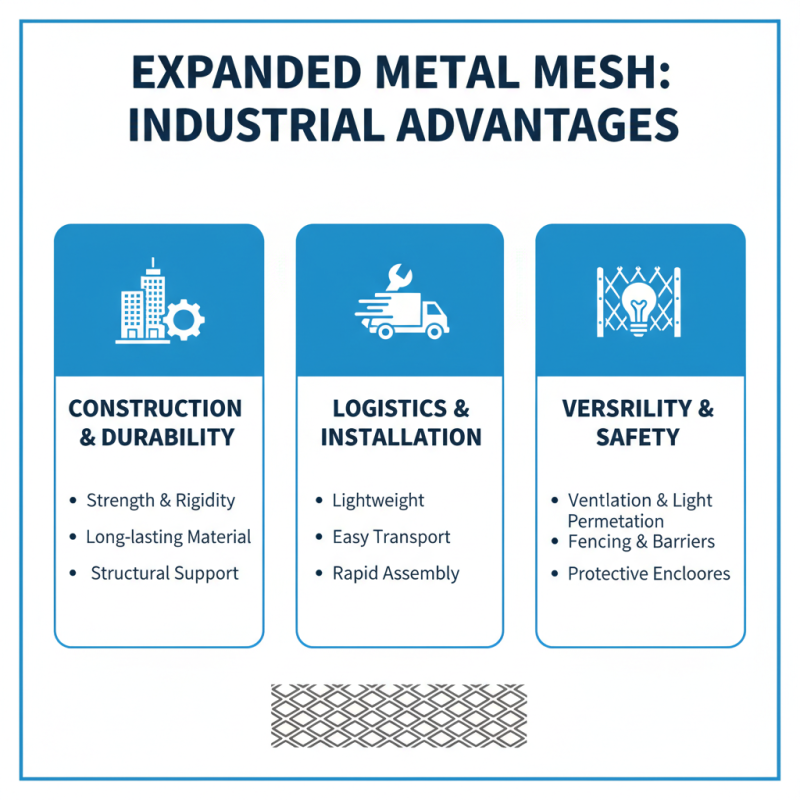

Benefits and Advantages of Expanded Metal Mesh in Various Industries

Expanded metal mesh is gaining popularity across various industries due to its unique attributes. This mesh offers durability and strength, making it ideal for construction. Its lightweight nature allows easy transportation and installation. Moreover, its rigid structure provides excellent ventilation and allows light to pass through. This makes it suitable for applications such as fencing and safety barriers.

The benefits of expanded metal mesh go beyond structural qualities. It’s cost-effective, requiring less material to produce than traditional solid materials. This reduces waste and costs in production processes. However, some may find it challenging to work with when precision is crucial. The variable openings can complicate measurements, especially in custom projects. Nonetheless, the mesh can be adapted for various uses. From walkways to architectural features, its versatility stands out clearly. Despite some drawbacks, the advantages often outweigh them, particularly for projects needing both strength and aesthetics.

Related Posts

-

How to Choose the Best Steel Stair Treads for Safety and Durability

-

What is Steel Wire Mesh Its Types Applications and Market Growth Trends

-

Understanding the Versatility of Perforated Sheets: Applications and Benefits in Modern Design

-

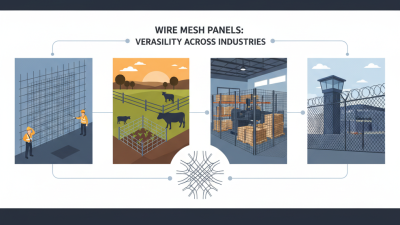

What is Wire Mesh Panels and How Are They Used in Various Industries

-

Understanding Expanded Metal: The Versatile Material Transforming Modern Architecture and Design

-

Exploring the Versatility of Perforated Steel Sheets in Modern Architecture and Design