Cart

What is Metal Mesh and Its Applications in Various Industries?

Metal mesh is a versatile material widely used across various industries. Its unique properties offer solutions in construction, automotive, and aerospace. A recent report from Grand View Research highlights that the global metal mesh market is expected to reach $3.2 billion by 2028. This growth indicates a rising demand for metal mesh in filtration, safety barriers, and decorative applications.

In industries like construction, metal mesh provides structural support and safety features. The automotive sector utilizes it for lightweight components, enhancing fuel efficiency. Aerospace applications leverage metal mesh for thermal protection and lightweight frameworks, reducing overall weight. According to a study by MarketsandMarkets, the aerospace segment is projected to expand at a CAGR of 5.9% from 2021 to 2026.

While metal mesh has numerous advantages, challenges remain. The production process can lead to inconsistencies in quality. Additionally, the cost of high-quality metal mesh can be prohibitive for some applications. As industries evolve, addressing these issues will be essential for maximizing metal mesh's potential. The future looks promising, but there is still room for improvement and innovation.

Definition and Properties of Metal Mesh

Metal mesh is a versatile material widely used across various industries. It is composed of interlinked metal strands that form a robust, open grid structure. The properties of metal mesh include high strength, durability, and resistance to corrosion. These features make it suitable for applications ranging from construction to filtration.

In construction, metal mesh provides structural support. According to a 2021 industry report, metal mesh can enhance load-bearing capabilities by up to 30%. This is crucial in achieving safety and stability in buildings. In the filtration sector, the high porosity of metal mesh allows for efficient separation of solids and liquids. A recent study indicated that metal mesh filters can capture particles as small as 5 microns.

In the aerospace industry, metal mesh also shows promise. It contributes to lightweight structures while maintaining strength. However, the production process can sometimes lead to inconsistencies in mesh quality. It's essential to ensure rigorous quality control measures are in place. These factors underline the need for continuous improvement in manufacturing techniques to fully utilize the potential of metal mesh in various applications.

Types of Metal Mesh and Their Manufacturing Processes

Metal mesh is commonly produced through various manufacturing processes that shape its properties and applications. The primary methods include weaving, welding, and perforating. Weaving involves interlacing wire strands to create a flexible grid. This technique allows for a variety of mesh types, from fine filters to heavy-duty screens. Welding, on the other hand, fuses wires at their intersections. This results in a more rigid structure, ideal for architectural and construction uses. Perforating involves punching holes into metal sheets, creating custom sizes and patterns often used in aesthetic applications.

According to a report by Grand View Research, the global metal mesh market is projected to reach around $5 billion by 2027. This growth indicates a rising demand across numerous industries, including construction, automotive, and aerospace. There are notable flaws in current manufacturing processes. For example, inconsistent wire quality can lead to variations in strength. Additionally, the environmental impact of certain manufacturing methods raises questions about sustainability. Balancing efficiency while minimizing ecological footprints is crucial. Industries must adapt their practices to meet both market demands and environmental responsibilities.

What is Metal Mesh and Its Applications in Various Industries?

| Type of Metal Mesh | Material Used | Manufacturing Process | Common Applications |

|---|---|---|---|

| Woven Wire Mesh | Stainless Steel, Aluminum | Weaving | Filtration, Screens |

| Expanded Metal Mesh | Carbon Steel, Galvanized Steel | Cutting and Stretching | Architecture, Fencing |

| Perforated Metal Mesh | Steel, Plastic | Punching | Noise Reduction, Decorative Panels |

| Wire Cloth | Brass, Bronze | Weaving | Sample Sieving, Laboratory Use |

| Hexagonal Wire Mesh | Galvanized Wire, PVC Coated Wire | Weaving | Chicken Coops, Landscaping |

Applications of Metal Mesh in Construction and Architecture

Metal mesh is gaining traction in construction and architecture for its versatility and aesthetic appeal. It offers an interesting blend of strength and lightness. Architects use it both structurally and decoratively. The mesh enhances buildings while allowing airflow and visibility.

Consider using metal mesh in facades. It can create unique patterns and textures. These elements can make a structure stand out. Additionally, metal mesh can improve energy efficiency. It can reduce heat gain in warm climates. However, it's crucial to consider material selection carefully. Not all metal types perform equally in different environments.

Tip: When integrating metal mesh, ensure it complements the overall design. Think about how it interacts with other materials, such as glass or brick.

Another application is in safety features. Metal mesh can function as a barrier or guardrail. This adds security while maintaining an open feel. Be mindful of the installation process, as improper fitting may lead to risks.

Tip: Always assess the mesh’s durability. Question whether it meets necessary safety standards. A small oversight can lead to bigger problems later.

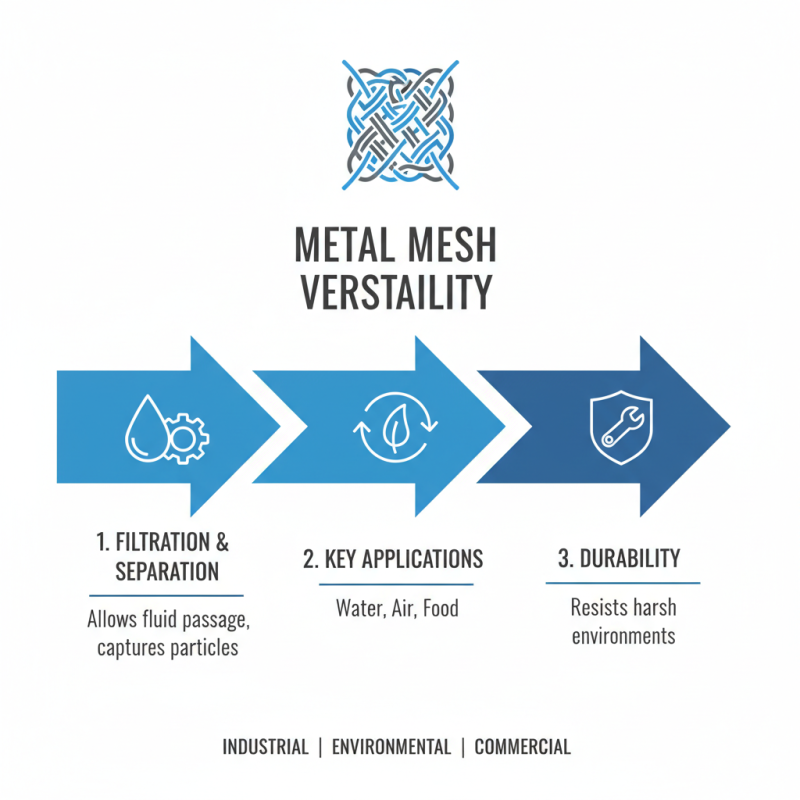

Role of Metal Mesh in Filtration and Separation Technologies

Metal mesh is a versatile material used in various industries for filtration and separation technologies. Its unique structure allows for the easy passage of fluids while effectively capturing unwanted particles. Metal mesh is often employed in water treatment, air purification, and even food processing. Its durability makes it ideal for environments where traditional materials might fail.

Tips: When selecting metal mesh, consider the size of the particles you need to filter. Choosing an appropriate mesh size is crucial for optimal filtration performance.

In air filtration systems, metal mesh plays a vital role. It helps trap dust and particulates, ensuring cleaner air output. However, not all metal meshes perform equally. Some may corrode faster than others or may not sustain high pressure effectively over time.

Tips: Regular maintenance is key. Inspect your metal mesh filtration systems periodically for signs of wear or damage. This ensures longevity and consistent performance. In some cases, upgrading the mesh might be necessary to keep up with evolving filtration needs.

Uses of Metal Mesh in Automotive and Aerospace Industries

Metal mesh is gaining traction in the automotive and aerospace industries due to its versatile properties. This material is lightweight yet highly durable, making it ideal for various applications. According to a recent report by MarketsandMarkets, the metal mesh market is projected to reach over $5 billion by 2025, driven by increasing demand for lightweight components.

In the automotive sector, metal mesh is used in wheels, exhaust systems, and filtration applications. Its ability to withstand high temperatures is crucial for performance and safety. Furthermore, it enhances airflow in engines, which can increase fuel efficiency. The aerospace industry also benefits from this material. Components like cabin screens and structural parts benefit from metal mesh's strength while minimizing weight. Reports indicate that aerospace manufacturers are increasingly adopting metal mesh to comply with strict regulatory standards.

Tip: When selecting metal mesh, consider the alloy type and mesh size. Different applications may require specific properties. Testing and certification should align with industry standards. Also, reflect on your needs. Sometimes, alternative materials can offer better cost efficiency.

Metal Mesh Applications in Automotive and Aerospace Industries

Related Posts

-

Top 5 Benefits of Using Metal Mesh for Your Home and Office Needs

-

Top Benefits of Using Weld Mesh for Construction and Home Projects

-

Exploring the Evolution of Metal Wire: From Ancient Craftsmanship to Modern Engineering Applications

-

2025 Top Trends in Metal Mesh Sheet Innovation for Industrial Applications

-

Top 10 Tips for Choosing the Right Steel Wire Mesh for Your Projects

-

Why Choose Steel Mesh for Your Construction Projects? Benefits and Applications Explained