Cart

What is Perforated Aluminum Sheet and Its Applications?

Perforated aluminum sheet is a versatile material with numerous applications across various industries. According to a 2022 market report, the demand for perforated metals is projected to grow significantly, driven by their unique properties. This lightweight alloy provides excellent strength and durability, making it ideal for both functional and aesthetic uses.

One notable application is in architectural design. Perforated aluminum sheets are used in facades and screens. They effectively control light and airflow, enhancing energy efficiency. Additionally, manufacturers benefit from reduced material waste due to the perforation process. This aspect aligns with sustainability goals.

Despite its advantages, challenges exist. The initial costs can be high, which may deter some industries. Furthermore, ensuring uniformity in the perforation patterns requires precision equipment, leading to additional investment. These factors are crucial to consider for businesses looking to integrate perforated aluminum sheet into their projects.

Definition and Composition of Perforated Aluminum Sheet

Perforated aluminum sheet is a unique material. It is made by taking aluminum sheets and creating various sized holes through a perforating process. This process can result in different patterns, shapes, and hole configurations. The composition of perforated aluminum involves high-grade aluminum, which ensures durability and resistance to corrosion. It is lightweight, making it easy to handle in various applications.

Applications of perforated aluminum sheet are diverse. It is widely used in architectural designs for facades and screens. The holes allow airflow and reduce wind pressure, making buildings more energy-efficient. In industrial settings, this material is often found in filters, grates, and sieves. Decorative panels are also popular, offering a blend of style and function. However, overusing this material in some environments can lead to issues with dust accumulation or reduced structural integrity if not designed properly.

With various thicknesses and hole sizes available, customization is key for specific needs. Designers often struggle with choosing the best patterns for functionality versus aesthetics. Balancing these requirements can be challenging. Each project presents its own unique demands, highlighting the importance of careful consideration in the design process.

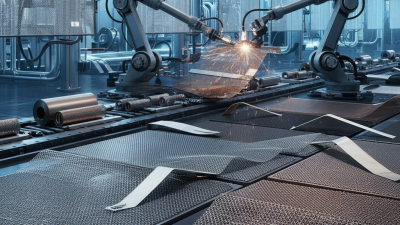

Manufacturing Process of Perforated Aluminum Sheets

Perforated aluminum sheets are made through a meticulous manufacturing process. The sheets start as flat aluminum panels that undergo perforation. High-precision equipment creates holes in the desired patterns. This process often utilizes CNC punching, optimizing production and reducing waste. Industry reports indicate that about 75% of perforated sheets are used in construction and architecture.

After perforation, the sheets undergo additional treatments. These can include anodizing or painting for enhanced durability and aesthetics. Reports suggest that anodized aluminum shows superior corrosion resistance. However, issues can arise during this coating process. Imperfections may occur if the surface is not properly prepared. The thickness of the sheet and size of the holes can also affect overall performance.

Manufacturers often focus on sustainability in production. The use of recyclable materials can minimize environmental impact. Nevertheless, challenges persist in sourcing eco-friendly aluminum. Reports show that while recycling is increasing, still around 40% of aluminum used today comes from non-recycled sources. This raises questions about long-term sustainability in this industry. Ultimately, while the perforated aluminum sheet has wide applications, the manufacturing process still needs continuous improvement.

Applications of Perforated Aluminum Sheet

Perforated aluminum sheets are widely used in various industries, with construction and automotive being the leading sectors utilizing these materials. This chart illustrates the percentage distribution of applications across different industries, showcasing their significance and utility.

Key Benefits of Using Perforated Aluminum Sheets

Perforated aluminum sheets offer a range of key benefits across various industries. These sheets are lightweight yet strong, making them ideal for applications that require durability without adding excess weight. According to a report by MarketsandMarkets, the global aluminum market is projected to reach around $182 billion by 2026, indicating a growing appreciation for materials like perforated aluminum.

One prominent benefit is their excellent aesthetic appeal. Designers frequently utilize perforated aluminum for architectural facades, allowing for creative ventilation while adding visual interest to buildings. Additionally, the sheets are resistant to corrosion. This durability makes them suitable for outdoor environments. In fact, studies show that aluminum maintains up to 80% of its original strength after years of exposure.

Cost-effectiveness is another significant advantage. While the initial investment can be higher than other materials, the longevity and low maintenance requirements offset ongoing costs. Moreover, while perforated aluminum sheets can sometimes lack the ruggedness of solid materials, their versatility makes them an attractive option in many applications. As industries evolve, it's imperative to assess both the benefits and potential limitations of using perforated aluminum sheets.

Common Applications Across Various Industries

Perforated aluminum sheets are widely used across various industries. Their unique design makes them ideal for several applications, from architecture to manufacturing. In construction, they serve as cladding and façade elements. The perforations allow for natural light penetration and ventilation, enhancing building aesthetics.

In the automotive sector, perforated sheets find their way into interior and exterior components. They help in weight reduction while maintaining structural integrity. Moreover, these sheets play a critical role in sound dampening. This is crucial for enhancing passenger comfort, especially in electric vehicles where noise control is essential.

In the food and beverage industry, perforated aluminum is common in equipment. It allows for easy drainage and airflow during processing. However, ensuring the right hole size and distribution can be challenging. Designers often grapple with choices that balance efficiency and safety, making this material both versatile and occasionally problematic.

What is Perforated Aluminum Sheet and Its Applications? - Common Applications Across Various Industries

| Industry | Application | Benefits |

|---|---|---|

| Architecture | Facades and Panels | Aesthetic appeal, light weight, weather resistance |

| Automotive | Grilles and Heat Exchangers | Improved airflow, reduced weight, corrosion resistance |

| Food and Beverage | Sifting and Screening | Hygienic, durable, various hole sizes for different applications |

| Construction | Railing and Guards | Safety, visibility, compliance with regulations |

| Mining and Industrial | Vibrating Screens | High load-bearing capacity, wear resistance |

| HVAC | Air Diffusers | Efficient airflow distribution, lightweight construction |

Maintenance and Care for Perforated Aluminum Sheet Products

Maintaining perforated aluminum sheets requires attention to detail. These versatile materials can resist corrosion, but they are not invincible. According to a report by the Aluminum Association, proper care can extend their lifespan significantly.

Regular cleaning helps prevent grime and dirt buildup. Use a soft brush or cloth with mild soap and water. Be cautious with abrasive materials; they can scratch the surface. For tough stains, a mixture of vinegar and water can work wonders. Avoid harsh chemicals, as they can lead to surface degradation over time.

Inspecting for signs of wear is crucial. Look for any bent edges or loose perforations. If you notice rust forming, address it quickly. A small issue can escalate into a bigger problem if neglected. A recent study by the International Aluminum Institute reports that neglecting maintenance can reduce performance by up to 40%. Making time for these tasks is not just beneficial; it is essential for longevity.

Related Posts

-

Understanding the Versatility of Perforated Sheets: Applications and Benefits in Modern Design

-

Exploring the Versatility of Perforated Steel Sheets in Modern Architecture and Design

-

What is Expanded Metal Mesh and Its Applications in Various Industries

-

What is Wire Mesh Panels and How Are They Used in Various Industries

-

2025 Top Trends in Metal Mesh Sheet Innovation for Industrial Applications

-

How to Choose the Right Metal Grate for Your Outdoor Project