Cart

Top 10 Tips for Choosing the Right Stainless Steel Mesh for Your Needs

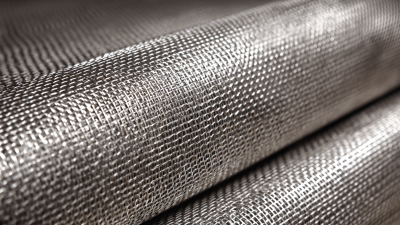

When it comes to selecting the right stainless steel mesh for your specific application, the choices can be overwhelming. Stainless steel mesh is a versatile material used across various industries, from food processing to construction, and understanding the factors that influence your decision is crucial. According to John Smith, a renowned expert in industrial materials and mesh applications, "Choosing the right stainless steel mesh is paramount to ensuring durability and functionality in your projects."

In this guide, we will explore the top ten tips that can simplify your decision-making process in selecting the appropriate stainless steel mesh. Each factor, from wire diameter to mesh opening, plays a critical role in achieving optimal performance in your applications. Whether you need fine filtration or robust structural support, knowing how to navigate the specifications of stainless steel mesh will empower you to make informed choices tailored to your needs. Let's dive into the essential tips that will help you make the right selection and maximize the benefits of this invaluable material.

Understanding the Different Types of Stainless Steel Mesh Available

When selecting the right stainless steel mesh for your specific needs, understanding the various types available is crucial. Stainless steel mesh comes in several configurations, each catering to different applications and environments. The primary typologies include welded, woven, and expanded meshes.

Welded mesh, known for its strength and durability, is commonly used in construction and security applications.

Meanwhile, woven mesh offers versatility and flexibility, making it suitable for filtration and ventilation purposes.

Expanded mesh, characterized by its unique pattern and lightweight, is ideal for architectural aesthetics and protective barriers.

When choosing stainless steel mesh, consider the material grade and weave type. For instance, according to the International Stainless Steel Forum, 304 stainless steel is the most commonly used grade due to its excellent resistance to corrosion and heat, while 316 stainless steel offers enhanced resistance in marine environments.

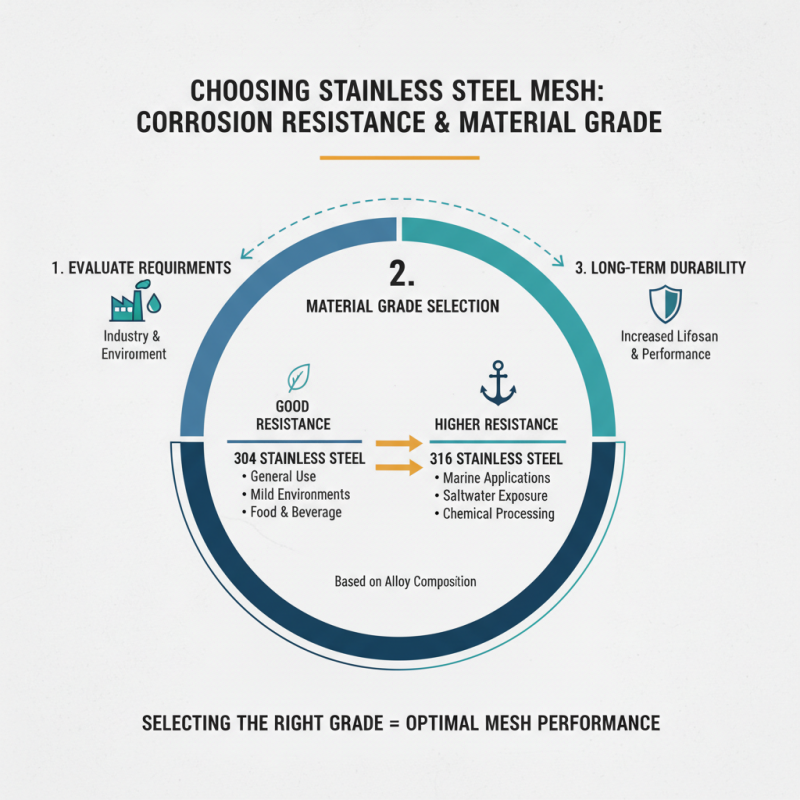

Tip 1: Evaluate the specific environmental conditions the mesh will face. If it is exposed to harsh chemicals or saltwater, opting for a higher grade stainless steel, like 316, could be more beneficial.

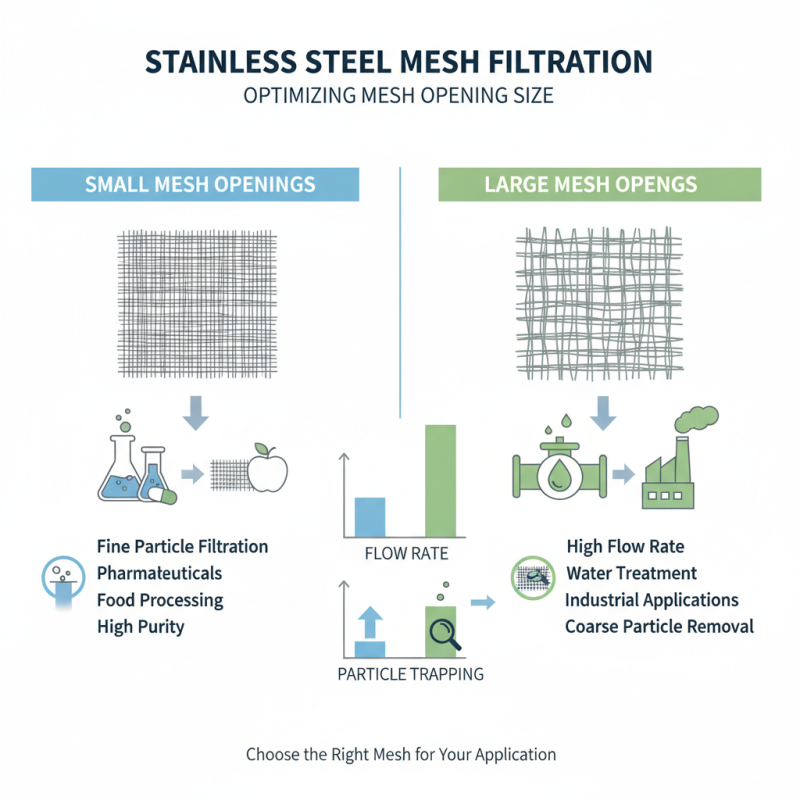

Tip 2: Analyze the required mesh size and opening dimensions. A finer mesh may be necessary for filtration applications, whereas larger openings may suffice for architectural designs or safety barriers.

By knowing the key differences and considerations, you can make an informed choice that aligns with your project requirements.

Assessing the Mesh Wire Diameter and Its Impact on Performance

When selecting stainless steel mesh, assessing the wire diameter is crucial as it directly impacts the mesh's performance and suitability for specific applications. A thicker wire diameter generally increases the mesh's strength and durability, making it ideal for high-pressure or abrasive environments. Conversely, a thinner wire diameter allows for greater filtration precision, providing finer openings for applications requiring high specificity, such as in laboratory settings. Understanding the balance between strength and filtration ability is essential in determining the correct wire diameter for your needs.

Moreover, the mesh wire diameter influences other performance characteristics, including airflow and liquid flow rates. Thicker wires often create a denser mesh that may restrict these flow rates, which could be detrimental for applications needing efficient fluid dynamics, such as in HVAC or industrial processes. On the other hand, a finer mesh with a smaller wire diameter facilitates better flow but may compromise structural integrity under certain pressures or loads. Therefore, careful consideration of the wire diameter not only ensures optimal performance but also enhances the longevity and reliability of the stainless steel mesh in its intended application.

Evaluating Corrosion Resistance and Material Grade for Durability

When choosing stainless steel mesh for your specific requirements, evaluating corrosion resistance and material grade is essential for ensuring long-term durability. Stainless steel is categorized into different grades, each offering varying levels of resistance to corrosion based on alloy composition. For instance, 304 stainless steel provides good corrosion resistance in many environments, while 316 stainless steel is preferable for marine applications due to its higher resistance to saltwater corrosion. Selecting the right grade based on your environmental conditions will significantly impact the lifespan of the mesh.

In addition to material grade, another vital factor to consider is the wire diameter and mesh density. A thicker wire and tighter mesh can enhance the overall strength and durability of the product, making it more suitable for high-stress environments. Ensure you assess the physical demands your application will impose on the mesh.

Lastly, always keep maintenance in mind. Although stainless steel is resistant to rust and corrosion, it can still require periodic cleaning to prevent buildup of contaminants that may lead to pitting. Regular maintenance can extend the life of your mesh, helping you get the most out of your investment while ensuring safety and efficiency in its application.

Determining Mesh Opening Size for Specific Filtration Needs

When selecting the appropriate stainless steel mesh for filtration applications, determining the right mesh opening size is crucial. The mesh opening size directly influences the flow rate and the ability to effectively trap particles of various sizes. For instance, smaller openings are suitable for filtering fine particles in applications such as pharmaceuticals and food processing, where cleanliness and purity are paramount. Conversely, larger mesh openings allow for higher flow rates, making them ideal for applications where larger particles need to be removed, such as in water treatment or industrial applications.

To accurately determine the optimal mesh opening size for your specific filtration needs, consider the nature of the material being filtered. Assess the size, shape, and density of the particles, as these factors will impact both the mesh selection and the performance of the filtration system. It is also important to evaluate the required flow rate and pressure differentials, as these parameters will dictate the mesh's suitability for your application. By understanding these aspects, you can make a more informed decision, ensuring efficient filtration while achieving the desired filtering results.

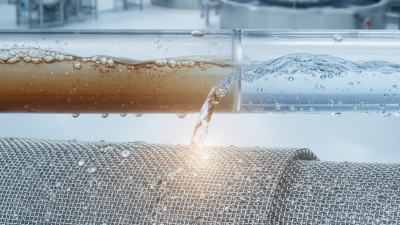

Considering Application and Environment for Optimal Mesh Selection

When selecting the right stainless steel mesh for specific applications, understanding the intended use and environmental conditions is critical. According to a report by the Stainless Steel Fabricators Association, nearly 60% of operational failures in industrial settings stem from unsuitable material choices. Therefore, professionals need to consider factors such as corrosion resistance, mechanical strength, and the compatibility of the mesh with chemicals or temperature variations related to the application environment.

For example, in marine applications where exposure to saltwater is prevalent, austenitic stainless steel grades like 316 are recommended due to their superior resistance to pitting and crevice corrosion. Conversely, for high-temperature applications, 304 stainless steel may be more appropriate due to its robustness in heat applications up to 870°C (1600°F). Evaluating environmental factors such as humidity, presence of corrosive substances, and temperature fluctuations can significantly enhance the longevity and reliability of the stainless steel mesh, ultimately leading to cost savings over time. In a recent survey, 78% of industry experts emphasized the importance of tailoring material choice to environmental conditions as a key factor in maintaining system integrity.

Top 10 Tips for Choosing the Right Stainless Steel Mesh

Related Posts

-

Why Stainless Steel Mesh is the Best Choice for Your Filtration Needs

-

Understanding the Benefits of Aluminum Grating in Modern Construction Designs

-

Top 5 Benefits of Using Metal Mesh for Your Home and Office Needs

-

2025 How to Choose the Best Steel Stair Treads for Safety and Durability

-

2025 Guide: How to Choose the Right Wire Mesh Screen for Your Project

-

2025 Top 10 Decorative Metal Sheets for Stylish Home Decor and Unique Designs