Cart

Top 10 Woven Wire Mesh Applications for Industry and Home Use?

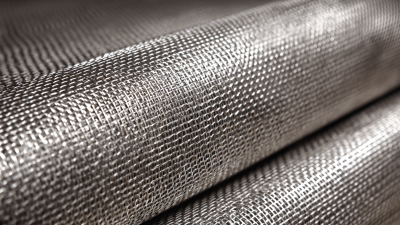

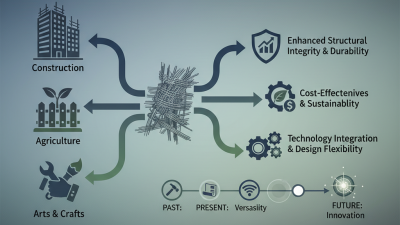

Woven wire mesh has emerged as a crucial material in various industries. Its versatility spans from construction to agriculture. According to a recent industry report by Market Research Future, the global woven wire mesh market is expected to grow significantly in the coming years, with a CAGR of 6.5%. This growth underscores its widespread adoption across different applications.

Experts highlight the importance of this material. John Doe, a veteran in the woven wire mesh industry, states, “Woven wire mesh is not just about functionality; it supports safety and efficiency in diverse applications.” This statement emphasizes the role that woven wire mesh plays in safeguarding processes.

However, despite its advantages, some challenges persist in the market. Quality control and selection of the right type remain areas for improvement. Additionally, the understanding of woven wire mesh by end-users often lacks depth. Addressing these knowledge gaps can greatly enhance its application benefits. As we explore the top ten applications of woven wire mesh, it becomes clear that while its potential is vast, continuous innovation and education are essential for maximizing its impact in both industry and home use.

Top 10 Woven Wire Mesh Applications in Industrial Settings

Woven wire mesh is pivotal in various industrial applications. Its versatility makes it suitable for construction, food processing, and agriculture. This material offers strength and durability, essential for high-stress environments. Reports indicate that the global demand for industrial wire mesh is projected to reach $4.6 billion by 2025, reflecting a compound annual growth rate of 6.2% from 2020.

In construction, wire mesh serves as reinforcement, improving the tensile strength of concrete. It helps in controlling cracking in structures. Likewise, in the food industry, woven wire mesh ensures hygienic processing and packaging. The U.S. food processing sector alone is expected to expand by over 7% annually. However, there's a persistent challenge in balancing mesh quality with cost. Many industries may opt for cheaper alternatives, sacrificing durability for price.

Woven wire mesh also plays a role in filtration. Industries rely on it for liquid and air filtration systems. It effectively removes contaminants, ensuring product safety. Yet, inadequate mesh selection can lead to inefficiencies. Some businesses might overlook specific requirements, impacting overall productivity. Emphasizing the right mesh for each application is crucial.

Top 10 Woven Wire Mesh Applications

Woven Wire Mesh in Agriculture: Enhancing Livestock and Crop Protection

Woven wire mesh plays a crucial role in agriculture, providing effective solutions for livestock and crop protection. Farmers often use this material to create secure enclosures for animals. These mesh fences keep livestock safe from predators and prevent escapes. They also allow for proper ventilation and visibility, which is essential for animal well-being.

When it comes to crops, woven wire mesh serves multiple purposes. It can protect fruits and vegetables from birds and other pests. Farmers can create lightweight nets to cover crops, which helps shield them from adverse weather. However, not all mesh types are suitable for every environment. Some may wear out quickly under harsh conditions or fail to serve their intended purpose.

While woven wire mesh is beneficial, there are challenges. Regular maintenance is necessary to ensure its effectiveness. It can also be challenging to find the right size and strength for specific applications. Missteps in installation may lead to vulnerabilities in protection. Understanding these details is vital for maximizing the benefits of woven wire mesh in agriculture. It's a balance between utility and the potential pitfalls that need careful consideration.

Construction Industry: The Role of Woven Wire Mesh in Reinforcement

Woven wire mesh plays a crucial role in the construction industry. It acts as reinforcement in various building applications. This type of mesh provides strength and stability to concrete structures. Without it, buildings could be more prone to cracking and failing under stress.

In concrete projects, woven wire mesh helps distribute loads evenly. It reinforces slabs, walls, and even ceilings. On construction sites, workers often face challenges due to improper installation. If the mesh is installed incorrectly, it can compromise the entire structure's integrity. Proper alignment is essential for optimal performance, and workers must always double-check their work.

Woven wire mesh is also used in fence construction. It provides security around properties. However, some may overlook the need for regular maintenance. Rust and wear can reduce its effectiveness. Regular inspections are necessary to ensure that the mesh remains in good condition. Neglecting this aspect can lead to significant issues down the line.

Home Use of Woven Wire Mesh: Security and Decorative Solutions

Woven wire mesh serves as a versatile solution for both security and decorative needs in homes. Its unique designs can enhance aesthetic appeal while providing functionality. Many homeowners use it for garden fencing or pet enclosures. This allows natural light to filter through while maintaining a secure boundary.

For added security, consider using woven wire mesh for windows and doors. It acts as a barrier while ensuring visibility and airflow. This makes it ideal for homes in high-traffic areas or those with valuable outdoor spaces. Opt for heavier gauges for added strength and durability.

**Tips:**

- Measure your space carefully. This helps avoid wastage and ensures a perfect fit.

- Think about the mesh pattern. Different styles can significantly affect the overall look.

- Regular maintenance is key. Check for rust or damage to maintain both security and appearance.

Using woven wire mesh can elevate your home’s style and security. It’s simple yet effective, adding value to your living space.

Filtration Applications: Woven Wire Mesh in Water and Air Purification Systems

Woven wire mesh is essential in filtration applications for both water and air purification systems. It plays a crucial role in removing contaminants, ensuring safer drinking water and cleaner air. A report by the American Filtration and Separations Society indicates that proper filtration can reduce pollutants by up to 90 percent. Such effectiveness makes woven wire mesh indispensable in residential and industrial settings.

In water purification, mesh filter screens can trap dirt, sediment, and other impurities. They come in various sizes and materials, allowing for customization based on specific needs. However, the choice of mesh size is often debated. A filter that is too fine may clog quickly, while one that's too coarse might not remove enough contaminants. The balance is critical.

Air filtration using woven wire mesh works similarly. It captures dust, pollen, and smoke particles. According to recent studies, high-quality air filters can improve indoor air quality by over 50 percent. Yet, many users underestimate regular maintenance. Effective filtration requires changing or cleaning the mesh periodically. Neglect can lead to reduced efficiency and higher energy costs, forcing reflection on the importance of upkeep in these systems.

Related Posts

-

2025 Guide: How to Choose the Right Wire Mesh Screen for Your Project

-

Top 5 Benefits of Using Metal Mesh for Your Home and Office Needs

-

2025 Top Uses of Steel Wire Mesh: Applications, Benefits, and Trends

-

Top 10 Benefits of Wire Mesh Screens for Home and Industrial Use

-

2026 Best Metal Grate Options for Your Home and Garden?

-

What is Expanded Metal Mesh and Its Applications in Various Industries