Cart

What is Wire Mesh Panels and How Are They Used in Various Industries

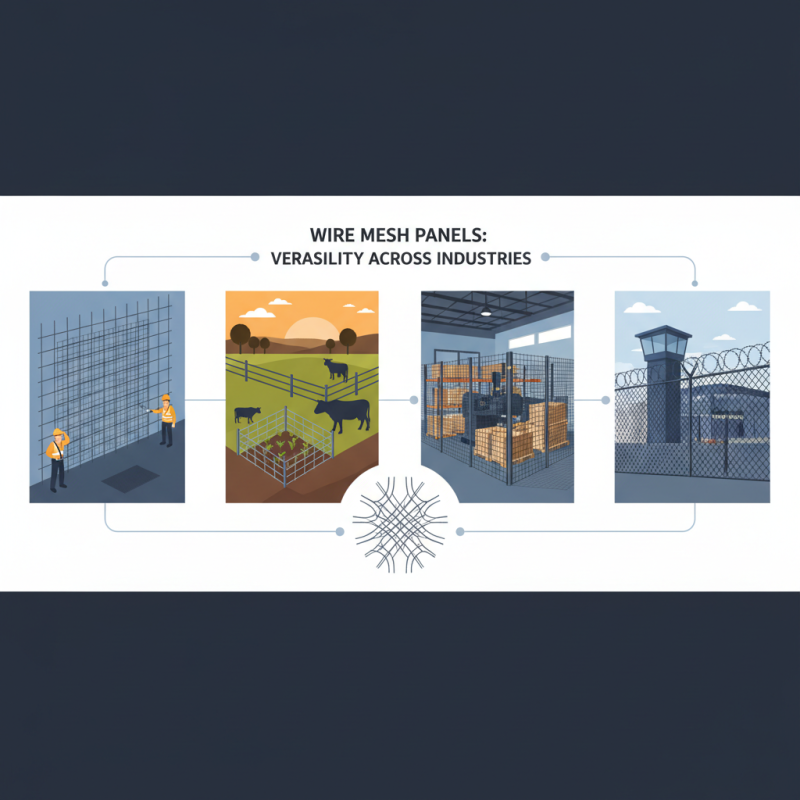

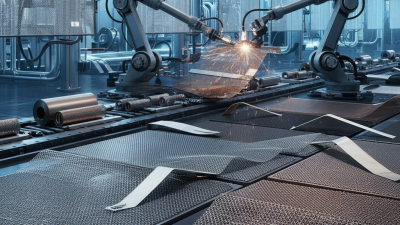

Wire mesh panels are versatile and practical solutions employed across a myriad of industries, showcasing their design flexibility and functionality. These panels are constructed from interwoven wire strands that form a grid-like structure, offering strength, durability, and the ability to support various applications. From construction sites and agricultural settings to industrial facilities and security installations, wire mesh panels serve as essential components that enhance safety, organization, and efficiency.

In construction, wire mesh panels are frequently utilized for reinforcing concrete, ensuring structural integrity and resilience in buildings and infrastructure. In agriculture, they provide an effective means for livestock containment and crop protection. Additionally, wire mesh panels play a crucial role in manufacturing and storage, offering secure barriers for equipment and materials while allowing for visibility and ventilation. These applications are just a glimpse into the widespread use of wire mesh panels across different sectors, demonstrating their importance in modern industry. As industries continue to evolve, the demand and innovation behind wire mesh panels remain strong, adapting to meet the dynamic needs of various applications.

Definition and Composition of Wire Mesh Panels

Wire mesh panels are versatile structures that consist of interconnected wire strands, forming a grid-like configuration. Typically made from materials such as stainless steel, galvanized steel, or aluminum, these panels offer durability and resistance to corrosion. The composition of wire mesh panels allows for various thicknesses and spacing, tailored to suit specific applications. While their designs may vary, the fundamental characteristic remains the same: a series of wires arranged in a uniform pattern, providing strength and accessibility.

In various industries, wire mesh panels are utilized for purposes ranging from safety and security to filtration and support. In construction, they serve as reinforcement in concrete structures, enhancing load-bearing capabilities without adding excessive weight. In agricultural settings, these panels may protect crops and livestock while also allowing for ventilation. Additionally, wire mesh is extensively employed in industrial environments for filtration processes, ensuring the integrity of diverse materials by allowing only desired particles to pass through. The adaptability and robust nature of wire mesh panels make them indispensable across numerous sectors, continually meeting the evolving needs of modern industry.

Common Types of Wire Mesh Panels and Their Characteristics

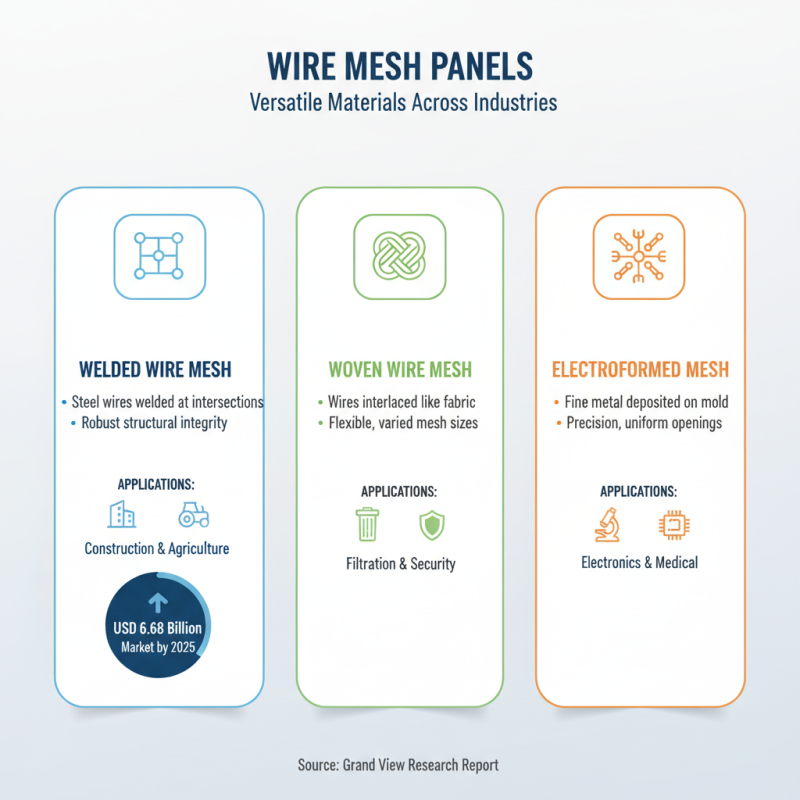

Wire mesh panels are versatile materials used across various industries, with their characteristics greatly influencing their applications. The common types of wire mesh panels include welded wire mesh, woven wire mesh, and electroformed mesh, each with unique features tailored to specific needs. Welded wire mesh, for example, consists of steel wires that are welded at intersections, providing robust structural integrity, which is especially valuable in construction and agriculture. According to a report by Grand View Research, the welded wire mesh market is projected to reach USD 6.68 billion by 2025, indicating a growing reliance on this material for safety and stability.

Woven wire mesh panels, on the other hand, are crafted from wires that are interlaced, offering flexibility and durability. This type is often utilized in filtration applications due to its varying strand sizes and open areas, which can be adjusted for specific filtration needs. The Global Market Insights report suggests that the demand for woven wire mesh in industrial filtration is expected to grow significantly, reflecting its essential role in maintaining quality and efficiency across manufacturing sectors. Meanwhile, electroformed mesh, characterized by its fine wire structure, is highly regarded in the electronics industry where precision and conductivity are crucial. These varied applications underscore the importance of wire mesh panels in modern industrial processes, adapting to specific demands while maintaining high performance standards.

Key Industries and Applications of Wire Mesh Panels

Wire mesh panels are versatile materials utilized across a range of industries for various applications. In the construction sector, these panels provide support and security, often used for fencing, reinforcement, and barriers. They are integral in creating sturdy frameworks and ensuring structural integrity in buildings and infrastructure projects. Additionally, in architecture, wire mesh panels can enhance aesthetic appeal while still serving functional purposes, such as sun shading or decorative screens.

In the agricultural industry, wire mesh panels are essential for managing livestock and protecting crops. They create enclosures that keep animals safe and contain them, while also preventing wildlife from accessing valuable crops. Moreover, in manufacturing and industrial settings, these panels are commonly employed for sorting, filtering, and separating materials as part of production processes. Their durability and adaptability make wire mesh panels ideal for applications ranging from safety barriers in factories to storage solutions in warehouses.

Advantages of Using Wire Mesh Panels in Various Sectors

Wire mesh panels are increasingly popular across various industries due to their versatile applications and distinct advantages. One major benefit is their durability; made from robust materials, they can withstand harsh environmental conditions. According to a report by the Global Wire Mesh Panels Market, the demand for wire mesh panels is projected to grow at a CAGR of 5.6% from 2021 to 2026, particularly in construction and agriculture. This growth reflects their effectiveness in providing safety barriers, fencing, and support structures, showcasing their critical role in enhancing security and improving operational efficiency.

In the manufacturing sector, wire mesh panels are used extensively in sieving processes, allowing for efficient sorting of materials while maintaining airflow. Their usage in industrial settings enhances productivity and reduces waste. Additionally, the food and beverage industry leverages wire mesh for filtration and containment purposes, ensuring compliance with health and safety standards. A specialized report indicates that industries using wire mesh panels can reduce maintenance costs by as much as 30%, thanks to their longevity and ease of replacement.

Tip: When selecting wire mesh panels for specific applications, consider the gauge and material type to ensure optimal performance and suitability for the environment. It's also beneficial to consult industry reports or professional guidance to choose the right specifications for your needs.

Installation and Maintenance Considerations for Wire Mesh Panels

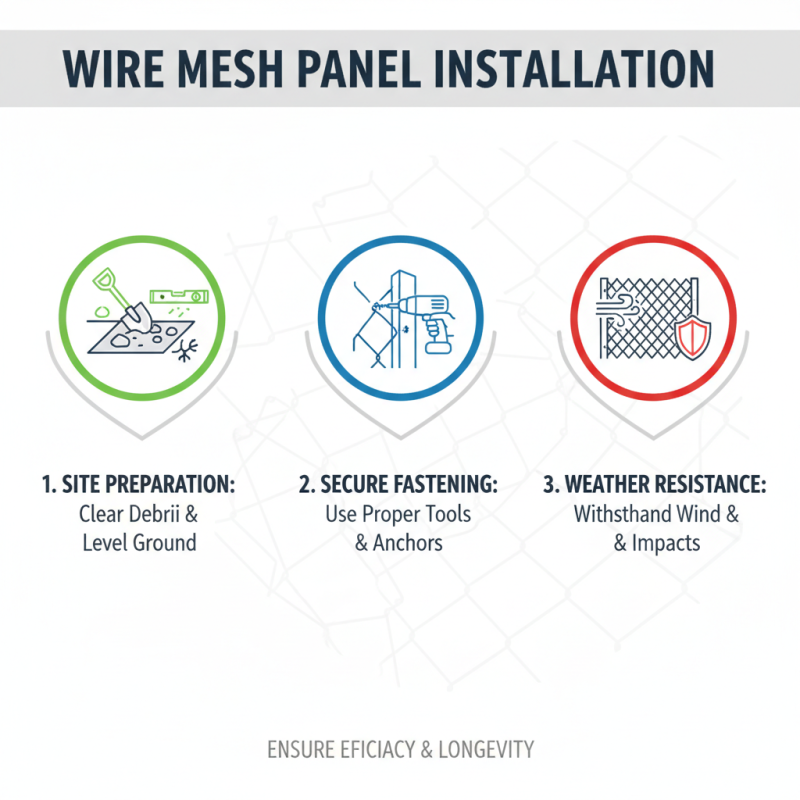

When it comes to the installation of wire mesh panels, several critical considerations come into play to ensure their efficacy and longevity. Proper site preparation is essential; this includes assessing the ground stability and ensuring the area is clear of debris and other obstructions. The panels must be installed on a level surface to maintain structural integrity and avoid unnecessary strain that could lead to warping or damage. It is also important to securely fasten the panels, using appropriate tools and techniques, to withstand environmental factors such as wind or impacts.

Maintenance of wire mesh panels is another essential aspect that can significantly extend their lifespan. Regular inspections should be conducted to identify any signs of wear, rust, or physical damage. Cleaning the panels periodically is crucial, as accumulated dirt and debris can compromise their effectiveness, especially in environments where hygiene is critical, such as food processing or medical facilities. Any damaged sections should be repaired promptly to prevent further deterioration, ensuring that the panels continue to serve their intended purpose effectively across various applications. Regular maintenance checks can help catch minor issues before they escalate, providing a safer and more reliable solution in any industry setting.

Related Posts

-

2025 Guide: How to Choose the Right Wire Mesh Screen for Your Project

-

2025 Top Trends in Metal Mesh Sheet Innovation for Industrial Applications

-

What is Steel Wire Mesh Its Types Applications and Market Growth Trends

-

Understanding the Benefits of Aluminum Grating in Modern Construction Designs

-

10 Essential Tips for Choosing Plastic Grating for Your Project

-

Exploring the Versatility of Perforated Steel Sheets in Modern Architecture and Design